11/01/10

External Access System

13

Appendix A

2. Installation

2.1 Any newly installed rail and trolley system used should be tested, certified and approved to

a recognised European Union standard for fall protection equipment (EN795; 1996; Class

D) and should display the CE mark. More information on these requirements is contained

in Annex 2.

2.2 Where it is proposed to use a rail and trolley system, or other system, (ie. a system already

fitted) that has not been specifically designed for supporting crew members over the side,

its use for overside work is not permitted without written confirmation having been received

from the manufacturer, preferably by means of a certificate, that use for such purposes is

permissible including any conditions attached to its use for that purpose.

3. Operation

3.1 Before use the employer should ensure that:

3.1.1 the manufacturers’ instructions are read and understood by the persons who will be

using the equipment;

3.1.2 a risk assessment is carried out and an appropriate rescue plan developed to

recover persons who fall into the water; and

3.1.3 crew members are competent to use the equipment and are aware of any

conditions relating to its use and their safety.

3.2 Rail and trolley systems for working overside should not be used whilst the vessel is

underway.

3.3 These systems are designed to be used with the appropriate PPE (harnesses, lanyards,

fall arresters and other devices).

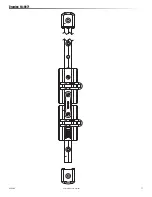

3.4 On systems referred to in paragraph 2.1 there is a single attachment on each traveller

designed to accommodate a single line such as a harness. One of the travellers is fitted

with a locking device. The device which locks the traveller in position along the track rail

must

ONLY

be disengaged from the track rail while the user is changing position. Once the

user is in position, the locking

MUST

be re-engaged to hold the car in position and limit the

user’s movement along the track rail.

3.5 The user must

NEVER

rely on only one attachment point for personal protective

equipment. The working harness should be attached to one traveller and a fall arrestor, or

other safety device, to the other. A third traveller could be used to attach work tools.

3.6 More guidance can be found in the Code of Safe Working Practices Chapters 4 and 15.

3.7 The use of systems for overside work that do not meet the requirements of either

paragraphs 2.1 or 2.2 above, or fail to provide instructions in the use of such equipment in

accordance with paragraph 3.1, could potentially place the employer of the crew, and also

the master, in breach of their obligations under relevant Merchant Shipping health and

safety legislation and render them liable to prosecution and a fine for non-compliance.

Further information on relevant legislation is set out in Annex 1.

4. Maintenance

4.1 Where systems meeting the requirements of either paragraphs 2.1 or 2.2 are used for

overside work, relevant information regarding the maintenance and testing of such systems

should be obtained from the system manufacturer. Such information is to be in written form

and a copy of it is to be kept on board the vessel to which it applies.

4.2 More information on the use of these systems is contained in Annex 2.

- 2 -