06/29/09

External Access System

3

1) Applications

A PURPOSE

The track and car system is designed for use

as an adjustable anchorage point for external

access to facilitate external maintenance

on vessels.

The system has two anchorage points. One

anchorage point for a personal suspension

system and the second for the fall-arrest

system.

Free Fall:

Personal fall arrest systems used with this equipment must be rigged to limit the free fall to

no more than 1.8 m (6 ft). Personal Suspension System must be rigged so that no vertical free fall is

possible.

Fall Clearance:

There must be sufficient clearance below the user to arrest a fall before the user strikes the

ground or other obstruction. Height of user plus extended safety lanyard length must not be more than the

height from rail to ground minus 2 m (6.5 ft).

Swing Falls:

Minimise swing falls by working as close to the anchorage point as possible.

Training:

This equipment must be installed and used by persons trained in its correct application and use.

2) System Requirements

C STANDARDS

This system has been tested to EN795 standard and is appropriate for single person use with an energy absorber

to EN355.

Harken equipment is designed for use with Harken approved components. Substitutions or replacements made

with non-approved components may jeopardize compatibility of equipment and may affect the safety and reliability

of the system.

Connectors (hooks, carabiners and D-rings) must be capable of supporting at least 22kN (5000 lbs), in

accordance with EN362.

Personal Fall Arrest Systems used with this equipment must meet EN813 requirements and include a shock-

absorbing lanyard (to EN355 standard) and a full body harness (to EN361, EN358, EN813 standard).

WARNING:

Consult Harken when using this equipment in combination with components or subsystems

other than those described in this manual. Altering or intentionally misusing this equipment may cause

the system to fail which can cause a fall which could result in severe injury or death.

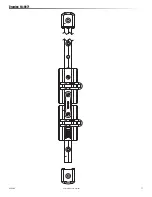

1. FuLL-BoDy SAFETy HARNESS

Use a full-body safety harness attached

to access car with pinstop.

Full-body safety harness must meet

/ANSI support standards.

2. WoRkING HARNESS

Use a working harness or chair attached

to access car.

Working harness or chair must meet

/ANSI support standards.

3. TooL SERvICE CAR

Add an optional car and coupler to work as

your tool service carrier.

B LIMITATIONS

Capacity:

This system is designed for use by one person with a combined weight (clothing, tools etc) of no more

than 100kg (220lbs). No more than one person may be connected to a two-car assembly at one time.

1

2

3