2

Intended Use -

use of

the device according to the

information supplied in the

instructions for use.

Improper Use

-

use of the

device in a way different from

that indicated in the

instructions for use.

Qualified Operator -

people who have attended

specialisation, training,

courses, etc. and are qualified

for using lifting people devices

to the current regulations of

the Nation in which the device

is used for rescue.

General User -

a user that

use the device to lifting loads

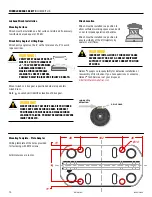

Text preceded by the following

symbols contains very

important information or

instructions, especially in

regards to safety.

Failure to observe these

may lead to:

- danger for operators

- invalidity of the contract

warranty

- refusal of the manufacturer

to accept responsability

ABOUT THIS MANUAL

This User Manual is an integral part of the device

and aims to provide all the information needed for

its safe and correct use and for proper maintenance.

If there are instructions you do not understand,

contact Harken.

Keep the manual in a safe place for future

consultation. This manual may be modified without

notice. Updated versions are available on

harkenindustrial.com.

This manual is for qualified operators (refer to the

Safety Information chapter for more information).

Improper use of the device or incorrect maintenance

could cause severe damage or death.

Harken accepts no responsibility for damage,

personal injury or death caused by failure to observe

the safety information and instructions in this Manual.

The manufacturer cannot be liable for damage,

injury or consequential loss resulting from

installation or servicing by unqualified personnel.

The manufacturer will also not be liable for damage,

injury, or consequential loss resulting from incorrect

operation or modification of the equipment.

Glossary and Terms & Symbols