5

ENGLISH

05/15/2022

SAFETY INFORMATION

General Advice

Use of the LokHead Winch for lifting people, in rescue situation,

is restricted to qualified operators who have attended specialist,

training, courses, etc. and are qualified for using rescue lifit-

ing devices to the current regulations of the Nation in which the

device is used for rescue.

Use of the LokHead Winch for lifting loads is permitted to a

general user in accordance with National Regulations & Working

Guidelines/Practices.

Harken is not responsible for damage caused by the LokHead

Winch to people, animals or property in the case of:

use of the LokHead Winch by operators not qualified

operators for liting people

improper use of the LokHead Winch

lack of proper maintenance, as indicated in the Maintenance

chapter of this Manual

unauthorised modifications or changes

use of spare parts that are not original or specific for the

model

total or partial failure to observe the instructions

usage contrary to specific national regulations

Intended Use

This winch is designed to be used as a manually powered,

rope-handling winch for lifting, lowering, and pulling loads.

Moreover the LokHead Winch is designed and compliant to

be used in rescue operation, by a qualified operator.

The LokHead Winch must be used after being mounted on a

suitable anchorage point.

All the equipment and anchor devices used in conjunction with

the Lokhead winch to lift person in rescue operation, must be

certified for their intended use in the rescue operation.

Improper Use

The winch must not be used:

for purposes different from those outlined in “Intended use”

chapter, or for purposes not mentioned in this manual or

different from those mentioned

if unauthorised modifications or interventions have been

carried out

in an explosive atmosphere

after it has fallen from a height of more than 1 meter onto a

hard surface. In this case the device must be returned to the

manufacturer or to a Harken authorised repair centre

with wire rope

with load in excess of the maximum working load, (reference

to the NFPA certification from UL) 485 lbs for lifting persons

in rescue operation

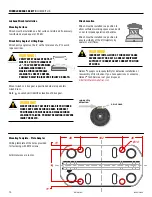

WARNING!

SUBJECTING THE WINCH TO LOADS ABOVE THE

MINIMUM BREAKING STRENGTH (MBS) CAN CAUSE

THE WINCH TO FAIL OR PULL OFF THE MOUNTING

SURFACE SUDDENLY, POSSIBLY RESULTING IN SEVERE

INJURY OR DEATH.

Personal Protective Equipment (PPE)

It is necessary use gloves when operating the device.

Residual Risks

You must pay attention to the following residual risks present

when using LokHead Winch:

WARNING!

ROTATING PARTS TRAPPING RISK

ALWAYS WEAR CLOTHING AND PROTECTIVE GLOVES

THAT ARE FORM FITTING. AVOID LOOSE GLOVES OR

CLOTHING AND ALWAYS FOLLOW THE INSTRUCTIONS

IN THIS MANUAL.