8

ENGLISH

05/15/2022

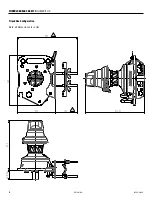

Tripod Use Configuration

Note: all dimensions are in mm.

WINCH LOKHEAD 500 KIT

INLH500KIT.US

e

R

®

i

SM

A

Tolleranze per dimensioni lineari ed angolari prive di indicazione di tolleranza specifiche come da Tab. UNI EN 22768-1 -Classe di tolleranza Media.

Tolerance for linear and angular dimensions without individual tolerance indications as for standard sheet UNI EN 22768-1 -Tolerance class m.

Tolleranze geometriche per elementi privi di indicazione di tolleranze specifiche come da Tab. UNI EN 22768-2 - Classe di tolleranza K.

Geometrical tolerance for features without individual tolerance indications as for standard sheet UNI EN 22768-2 -Tolerance class K.

A - Modificato descrizione da 500KIT HL a 500.US e rimosso S721750020 e A97016100 (Baselli 31/01/2020)

B - Sostituito u-bolt (Baselli 04/11/2020)

Tolleranze generali per fori H13 UNI EN ISO 286-1

Holes general tolerance H13 UNI EN ISO 286-1

Tolleranze generali per alberi h13 UNI EN ISO 286-1

Shafts general tolerance h13 UNI EN ISO 286-1

La HARKEN SPA è proprietaria esclusiva di questo disegno e di tutte le informazioni in esso contenute. A norma di legge è vietata la riproduzione senza autorizzazione scritta rilasciata dalla HARKEN SPA.

HARKEN SPA is the sole owner of this drawning and of all included information. According to law it is forbidden to reproduce this drawing whithout a written authorization issued by HARKEN SPA

Smussi non quotati 0.2 x 45°.

All unmarked chamfers 0.2 x 45°.

Tutte le quote si riferiscono prima di eventuali

trattamenti superficiali

All dimensions refer to the moment previous to

surface treatments

Riferimento a specifiche Harken

Harken standard dependence

Raggi non quotati 0.5

All unmarked radii 0.5

Rompere spigoli vivi

Remove all sharpcorners

Q.ty

Code

Description

1

A97002700

Assy Plastic box with foam insert

1

A96910800W

Control lever assy

1

F83256700

Handle B10AL

POS.

QTY.

Code

Description

Weight (g)

1

1

A97035600

Assembly reversible plate LokHead 500KIT.US

2326.73

2

1

A97216400

Winch LokHead 500.US

4266.87

3

1

A97216500

Tripod adapter LokHead 500KIT.US

2291.07

B

B

Inclusi i seguenti codici non rappresentati:

Drawn

Note

Material

Description

Finish

Scale

Date

Filename

Rev.

Revision / Modification:

Mass [g]

0

10

20

30

40

50 [mm]

Code

C:\temp\

Mod.

Modelled

Checked

Date

Date

Surface [mm2]

ISO A2

Sheet format

872164

8884.68

1:2.5

Cazzaro

Baselli

04/11/2020

05/03/2019

Assieme Winch LokHead 500.US

Assembly Winch LokHead 500.US

0

F87216400

B

10

20

30

40

50

60

70

80

90

100 [mm]

F

E

C

D

A

B

5

6

7

8

3

4

1

2

11

10

9

12

G

H

B

E

C

F

G

A

D

Baselli

06/03/2019

48,50

262

203

262

323

120

310,50

e

R

®

i

SM

A

Tolleranze per dimensioni lineari ed angolari prive di indicazione di tolleranza specifiche come da Tab. UNI EN 22768-1 -Classe di tolleranza Media.

Tolerance for linear and angular dimensions without individual tolerance indications as for standard sheet UNI EN 22768-1 -Tolerance class m.

Tolleranze geometriche per elementi privi di indicazione di tolleranze specifiche come da Tab. UNI EN 22768-2 - Classe di tolleranza K.

Geometrical tolerance for features without individual tolerance indications as for standard sheet UNI EN 22768-2 -Tolerance class K.

A - Modificato descrizione da 500KIT HL a 500.US e rimosso S721750020 e A97016100 (Baselli 31/01/2020)

B - Sostituito u-bolt (Baselli 04/11/2020)

Tolleranze generali per fori H13 UNI EN ISO 286-1

Holes general tolerance H13 UNI EN ISO 286-1

Tolleranze generali per alberi h13 UNI EN ISO 286-1

Shafts general tolerance h13 UNI EN ISO 286-1

La HARKEN SPA è proprietaria esclusiva di questo disegno e di tutte le informazioni in esso contenute. A norma di legge è vietata la riproduzione senza autorizzazione scritta rilasciata dalla HARKEN SPA.

HARKEN SPA is the sole owner of this drawning and of all included information. According to law it is forbidden to reproduce this drawing whithout a written authorization issued by HARKEN SPA

Smussi non quotati 0.2 x 45°.

All unmarked chamfers 0.2 x 45°.

Tutte le quote si riferiscono prima di eventuali

trattamenti superficiali

All dimensions refer to the moment previous to

surface treatments

Riferimento a specifiche Harken

Harken standard dependence

Raggi non quotati 0.5

All unmarked radii 0.5

Rompere spigoli vivi

Remove all sharpcorners

Q.ty

Code

Description

1

A97002700

Assy Plastic box with foam insert

1

A96910800W

Control lever assy

1

F83256700

Handle B10AL

POS.

QTY.

Code

Description

Weight (g)

1

1

A97035600

Assembly reversible plate LokHead 500KIT.US

2326.73

2

1

A97216400

Winch LokHead 500.US

4266.87

3

1

A97216500

Tripod adapter LokHead 500KIT.US

2291.07

B

B

Inclusi i seguenti codici non rappresentati:

Drawn

Note

Material

Description

Finish

Scale

Date

Filename

Rev.

Revision / Modification:

Mass [g]

0

10

20

30

40

50 [mm]

Code

C:\temp\

Mod.

Modelled

Checked

Date

Date

Surface [mm2]

ISO A2

Sheet format

872164

8884.68

1:2.5

Cazzaro

Baselli

04/11/2020

05/03/2019

Assieme Winch LokHead 500.US

Assembly Winch LokHead 500.US

0

F87216400

B

10

20

30

40

50

60

70

80

90

100 [mm]

F

E

C

D

A

B

5

6

7

8

3

4

1

2

11

10

9

12

G

H

B

E

C

F

G

A

D

Baselli

06/03/2019

48,50

262

203

262

323

120

310,50