11

Performa

™

Winch

60.3 STP EL/HY

Installation and Maintenance Manual - Mod.D

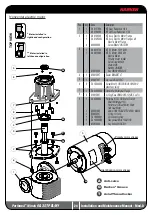

After winch is assembled and before sailing, test the powered winch functioning: insert the lock-in

winch handle in the handle socket and check that the disconnect rod must disconnect gearbox.

Electric equipment

To guarantee greater efficiency in terms of safety and long life, for every winch model is mandatory

to install the Dual Function Control Box.

To fasten the Dual Function Control Box containing solenoids to bulkhead or wall, for all

installation details and for all electric wiring schemes, refer to the Dual Function Control Box

manual.

WARNING!

Before installing and using the device, read carefully the Dual Function Control Box manual

available on web site www.harken.com

Refer to the following chart for wire size:

Total distance between winch and battery

Winch

size

Current

voltage

Under 16.4 ft

AWG

Under 5 m

mm

2

16.4 - 32.8 ft

AWG

5 m - 10 m

mm

2

32.8 - 49.2 ft

AWG

10 m - 15 m

mm

2

49.2 - 65.6 ft

AGW

15m - 20 m

mm

2

60.3

12 V

2

32

0

50

00

70

000

95

60.3

24 V

5

16

3

25

2

35

0

50

Refer to the following chart for HCP model:

Winch

size

Current

voltage

HCP model

Ampere

rating

60.3

12 V

HCP1720

135A

60.3

24 V

HCP1717

80A

NOTICE

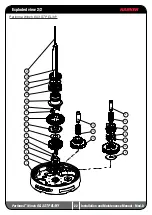

Before positioning the flange, check to

make sure that seals (the first one is above

the flange and the second one is under the

flange) are seated correctly.