7

Performa

™

Winch

50.2 STP EL/HY

Installation and Maintenance Manual - Mod.D

Procedure

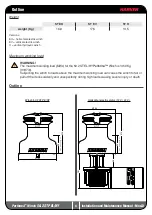

To install the winch, remove the drum and use Socket Head (SH) bolts.

Tools needed

One medium flat-bladed screwdriver

To identify the various parts, refer to the exploded view at the end of this Manual.

Torque to apply when assembling

Install the winch on the deck in the position you have chosen, keeping in mind the limits described

on page 4 and using socket head (SH) bolts.

1. Pull out the disconnect rod n°30

3. Slide off the assy socket n°29 and the cover

n°28. Pay attention to the o-ring in the socket.

5. Remove the stripper arm n°26 by

rotating and lifting it.

6. Lift off the drum n°23

2. Unscrew the central screw ( 2Nm/18 in-lb)

4. Unscrew the three screws n°27

( 4Nm/35 in-lb)