12

Riggers Winch 200

01/03/19

Disassembly

11. Slide off gear n°3

12. Slide off gear n°11

13. Unscrew the screw n°10 and remove

the washer n°9. (4 Nm/35 in-lb)

2. Remove jaws n°15.

1. Unscrew the 3 screws n°16

( 4 Nm/35 in-lb)

If it is necessary to replace winch jaws, proceed

as follows:

Torque to apply when assembling

Tools You Will Need

Medium flat-blade screw-

driver

REPLACING SELF-TAILING JAWS

Summary of Contents for Riggers Winch 200

Page 2: ...2 Riggers Winch 200 01 03 19...

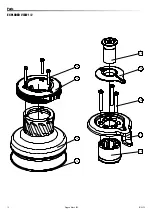

Page 18: ...18 Riggers Winch 200 01 03 19 Parts EXPLODED VIEW 1 2 14 13 15 16 12 17 18 19 20...

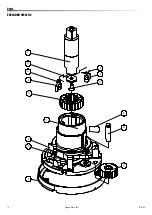

Page 19: ...19 Riggers Winch 200 01 03 19 Parts EXPLODED VIEW 2 2 2 1 4 5 11 4 5 7 3 6 10 9 8 4 5...

Page 22: ...22 Riggers Winch 200 01 03 19...

Page 23: ...23 Riggers Winch 200 01 03 19...