Exception F200 Wood Insert

6

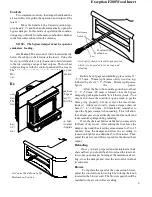

Controls

Two important controls - the damper handle and the

air control lever regulate the operation and output of the

insert.

Move the handle to the forward position (ap-

proximately 3") and the handle automatically opens the

bypass damper. In this mode of operation the combus-

tion gases go directly from the main combustion chamber

to the flue collar and exit into the chimney.

NOTE: The bypass damper must be open for

smokeless loading.

Air Control. The air control rod is located directly

below the ash lip on the left side of the insert. Using this

lever you will be able to vary the amount of air delivered

to the fire, creating a range of heat outputs. The low heat

output setting is with the control pushed all the way in.

The high setting is with the control pulled all the way out.

Do not, under any circumstances, alter the configuration

or operation of the air control rod.

Building and Maintaining the Fire

Set the air control lever at the maximum heat

output setting, all the way pulled out. Open the bypass

damper by pulling the handle forward (approximately 3").

The convection blower, if installed, should be off for the

first five minutes after a reload.

Do not use chemicals or fluids to

start the fire.

Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter fluid, or similar liquids to start

or “freshen up” a fire in this heater. Keep all such liquids

well away from the heater while it is in use.

Build a bed of paper and kindling; place several 1 "

- 2" (25 mm - 50 mm) split pieces of dry wood on top,

followed by a few 2" - 3" (50 mm - 80 mm) split pieces.

Ig nite

the

p ap er .

Allow the fire to burn until a good charcoal bed,

2" - 3" (50 mm - 80 mm) is formed; close the bypass

damper by pushing the handle "in" all the way back. (You

may need to leave the load door open a crack to get the

blaze going properly, but never leave the insert unat-

tended.) Add more wood to create a deeper charcoal

base (3" - 4", or 80 mm - 100 mm thick); remember to

open the bypass damper when loading. This will allow

the exhaust gases to pass directly into the flue outlet and

reduce smoke spillage during refueling.

Once the charcoal bed is established you may add a

full load of dry wood. After adding the fuel, leave the

damper open and the air setting at maximum for 5 to 15

minutes; close the damper and allow the air setting to

remain on high for an additional 5 to 10 minutes. Then

adjust the air lever and blower speed for the desired heat

output.

Reloading.

Once you have prepared and maintained a thick

charcoal bed, you should be able to reload the insert, al-

low some open damper burning at the maximum air set-

ting, close the damper and reset the air control in about

five minutes.

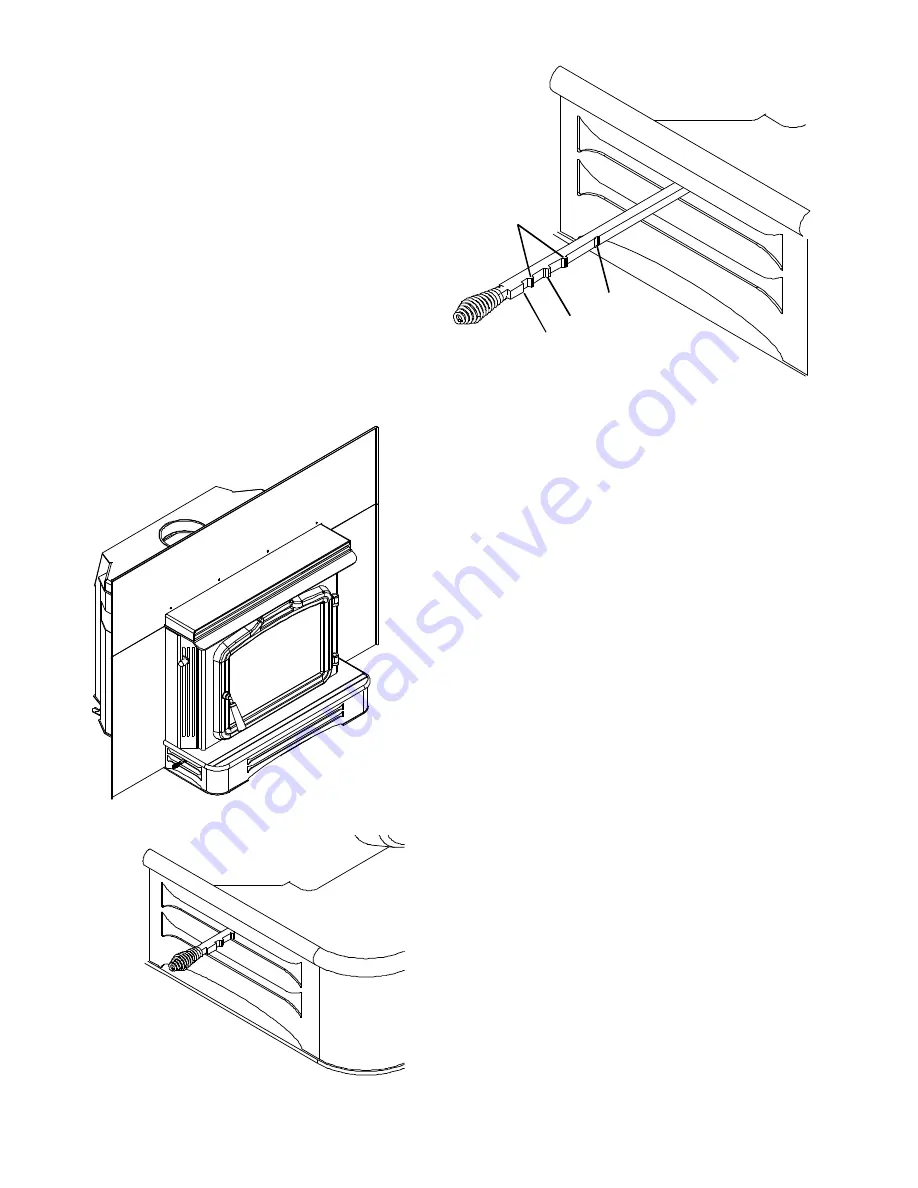

Blower.

To regulate the speed of the convection blower,

adjust the control from low to high by turning the knob

located on the blower cord. The blower speed should be

matched to the air control lever setting.

Air Control shown in the full open position

which is to be used only for start-up and

refueling

Air Control Rod Shown In The

Medium Low Position.

Low

Medium Low

Medium High

Reference

Notches

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.