Exception F200 Wood Insert

7

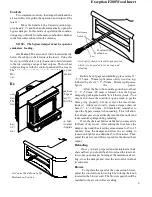

cause a fire. Overfiring is caused by:

1. Too much air flowing through the insert too

quickly.

2. You may have positioned the primary air control

level too far to the left.

3. Inadvertently left the damper open or

4. Not kept up with routine maintenance, such as

checking door gaskets for wear.

Overfiring results in excessive fuel consumption, and

may cause parts of the insert to glow red. If you notice

signs of overfiring, reduce the air supply to the fire, and

review the Maintenance section in this manual.

Never leave the insert unattended with the

door open. Overfiring may result.

In the event of a chimney fire, call your local fire

department; make sure everyone is safely out of the house.

Reduce the air intake of the insert as much as possible

using the air control lever; close the bypass damper to

further restrict air flow. Do not throw water on the fire;

this can cause insert damage and create an even more

dangerous situation. Have your chimney professionally

cleaned and inspected before resuming burning in your

insert.

Removing and Disposing of Ashes.

Before opening the door to remove the ashes, open

the bypass damper. Wearing heavy protective gloves,

remove ashes from the fire chamber periodically with a

small shovel. Close the door before taking the ashes out-

side for safe disposal.

A good time to empty the ashes is before loading.

This ensures that the ashes will be cold and safer to handle

than directly after poking the ashes down or tending the

fire.

Never let the ashes build up to over 2" in depth.

Excessive ash buildup can prevent proper venting of ex-

haust gases.

Ashes should be placed in a metal container with a

tight fitting lid. The closed container of ashes should be

placed on a noncombustible floor or on the ground, well

away from all combustible materials, pending final dis-

posal. If the ashes are disposed of by burial in soil or

otherwise locally dispersed, they should be retained in the

closed container until all cinders have thoroughly cooled.

Never use the ash disposal container for other trash.

Wood ash can be added to your garden or compost.

When the air setting is low, the blower should

always be at the minimum setting (corresponding to a

blower speed of 750 RPM.) At higher settings above

first notch the blower may be set to your desired comfort

level. Be sure that the blower cord does not run under,

over, above or in front of the insert.

The following guidelines for air settings can be

used for wood burning; as you become familiar with your

insert, you will know which settings best heat your home.

Minimum Burn Rate - air control fully to right.

Medium Low Burn Rate - air control pulled 1"

out to the second notch.

Medium High Burn Rate - air control puled out to

the fourth notch. This setting may be used to burn

wood that is damp in order to keep it burning, but

will consume seasoned, dry wood too fast.

High Burn Rate - air control fully pulled out. This

setting is for refueling and starting a fire. Continuous

burning at this setting will cause premature failure of

consumable parts such as the afterburner hood and

firebricks.

Note: At minimum burn rates the glass may get dirty

but will clean off again at higher burn rates.

After Burner Viewport.

This is a small ceramic glass window in the back

of the firebox. This window allows you to see the After-

burner Combustion System in action. This glass may

smoke up under some conditions but will burn off again.

It is OK if this glass is not totally clean.

Operating as a Fireplace.

The F200 is tested and approved to be burned with

the front load door open and the damper open. In this

mode of operation you get a true fire sound as well as

appearance. Due to the crackling and popping of burning

wood it is necessary to place the optional screen over the

door opening. This prevents sparks from entering the room

just like a screen over a fireplace.

The insert is hot while in operation. Keep

children, clothing and furniture away.

Contact may cause skin burns.

Overfiring

Avoid overfiring your insert, a potentially hazard-

ous situation which can lead to overheating of combus-

tible materials, damage to the insert, and in extreme cases,

Curing Paint.

As you begin to operate your insert at higher

temperatures, you will notice a “hot” or unpleasant

smell; this is just the paint going through the cur-

ing process, and will disappear after a few fires.

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.