Exception F200 Wood Insert

8

Like all fine equipment, your Exception requires

some routine maintenance and inspection. Follow the

guidelines in this section to guarantee safe, efficient

operation.

The Insert

Surface

The insert’s exterior surface should be dusted

periodically with a soft cloth. For more thorough clean-

ing, wait until the insert is cool before using a damp cloth

to clean any blemishes.

The Door

The gold plated front door should never be buffed

or polished. Abrasive cleaners and metal polishes will

remove the plating and therefore should never be used. If

the door needs to be cleaned, wait until the insert is com-

pletely cool, then use a sponge, soap and water to gently

remove dirt and stains. Before relighting the insert, re-

move all soap residue and wipe dry.

Controls

To avoid a rust buildup on the inner surfaces of

the controls, work the controls back and forth several

times, during the summer, or any prolonged period when

you are not using your insert.

The Fire Chamber

The inside of the fire chamber should be exam-

ined for damage to the refractory lining material, After-

burner hood and Afterburner glass. If any of these parts

have been damaged, replace them with Harman Stove

Company replacement parts.

Glass - Replacement

If the insert’s glass is cracked or broken, you must

replace it before operating your insert. Remove pieces

carefully. Replace glass only with Harman Insert Com-

pany replacement glass panels; do not use substitutes.

To replace the glass panel(s), you will need to

remove the door. To do this, open the door, lift it straight

up and place it on a soft surface.

Carefully remove damaged glass, gasket material,

and hold down clips (set aside).

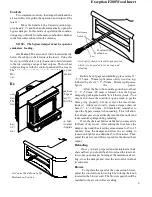

Referring to the diagram, note how the various com-

ponents of the door system fit together. Lay the load

door face down on the soft surface, and install the self

adhesive 1/4"” gasket material around the front face of

the glass. Note: This glass has a special IR coating on

one side. This coating must be to the outside of the in-

sert. The coated side has a label on it. Do not remove the

label before installing the glass. Remove label before

burning the unit.

Set the glass pane and gasket gently onto the door.

Install the hold down clips and tighten with bolts as shown.

Reinstall door on insert.

Glass - Cleaning

Sometime it will be nec-

essary to clean accumulated ash

from the glass surface; allowing

this ash to remain on the glass

for long periods can result in

“etching” due to the acidity of the

ash. The creosote which accu-

mulates on the glass should burn

off during your hot fires.

Never clean the glass

while it is hot, and do not use

abrasive substances. Wash the

surface with cool water, and

rinse thoroughly. You may wish

to use a nonabrasive cleaner spe-

cifically designed for use on in-

sert glass. In any case, dry thor-

oughly before relighting your in-

sert.

Maintenance

Door

Glass Gasket

Glass

Hold Down Clips

and Bolts

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.