Exception F200 Wood Insert

9

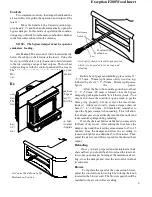

Gaskets

Gaskets are used at strategic positions when build-

ing the Harman Exception for controlling the path that

incoming and outgoing air and gases take through the in-

sert. You must check these gaskets from time to time,

and replace them when necessary. The gaskets are made

of fiberglass of different sizes (obtainable from Harman

Stove Company) and are fixed in place with a high tem-

perature gasket cement. To change a gasket, first re-

move the worn fiberglass and clean the area with a wire

brush. Also clean any other surfaces that come into con-

tact with the gasket. Place a small bead of cement in the

area under the gasket, then press new gasket material

into the channel; do not overlap the ends. Seat the gasket

firmly by applying pressure when possible; for example,

after changing the door gasket, close the door. Allow the

cement to dry before using your insert.

Gaskets are located on the door to provide airtight

closure and between the damper and the damper

frame.

Handle

The handle on the front door of your Exception is

attached to threaded shafts. After a period of time, you

may find that the front door does not close as firmly as

when your insert was new. This is due to a natural com-

pression of the gaskets. To tighten the seal, open the

door and rotate the handle one full turn counterclockwise

or bend the latch plate on the insert.

The Chimney System

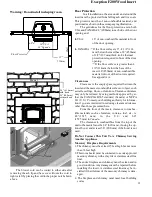

Creosote Formation And Need For Removal

When wood is burned slowly, it produces tar and

other organic vapors, as well as soot, which combine with

expelled moisture to form creosote . The creosote va-

pors condense in the relatively cool chimney flue (associ-

ated with a slow burning fire). As a result, creosote ac-

cumulates on the flue lining. When ignited, this creosote

can result in an extremely hot fire.

The afterburner on the Exception cuts creosote to

almost nothing when properly burned with dry seasoned

wood.

The chimney should be inspected at least once

every two months during the heating season to see if any

creosote buildup has occurred. Checking your chimney

and chimney connector more frequently, especially while

you are getting used to your insert, is recommended. To

inspect this system, let the insert cool. Using a flashlight

and mirror, check the interior of the chimney connector,

and the chimney itself. If a significant layer of creosote

or soot as accumulated (1/8"” or 3 mm) it should be re-

moved to reduce the risk of a chimney fire.

To clean deposits from the surface of the con-

nector, use a stiff wire brush after dismantling the con-

nector assembly. To clean the chimney, use a specially

designed brush sized to fit your particular flue opening, or

call an established chimney cleaning service.

At the end of the heating season, perform a thor-

ough examination of your chimney system, and have it

repaired if necessary.

Do not burn any fuel other than wood, such as char-

coal, which can cause increased carbon monoxide pro-

duction or overfiring. Never use highly volatile substances

in your insert, such as gasoline, which could cause an

explosion.

When solid fuels are burned completely, they pro-

duce water and carbon dioxide. However, in long slow

burns, a substantial amount of carbon monoxide may be

produced. If allowed to build up, carbon monoxide (which

is odorless) can prove fatally poisonous. Proper ventila-

tion and draft will prevent this from happening. If you

smell smoke, turn up the air control lever setting, and thor-

oughly ventilate your dwelling. During future burns, be

careful not to overload the insert with fuel, so you will not

be tempted to constantly operate at a low air control set-

ting.

Other causes of poor ventilation or draft are icing,

exhaust fans, a blocked outside air inlet, and room air

starvation. If your insert is sluggish and you get occa-

sional odor, check these possibilities and increase the air

flow in your home.

Proper Ventilation

Always provide a source of fresh air to the room

when the insert is operating.

Blower

The blower on your Harman Exception insert

requires very little maintenance. You should, however,

keep the air inlet and the motor free of dust.

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.