32

INSTALLATION (Options)

Only For Qualified Installers

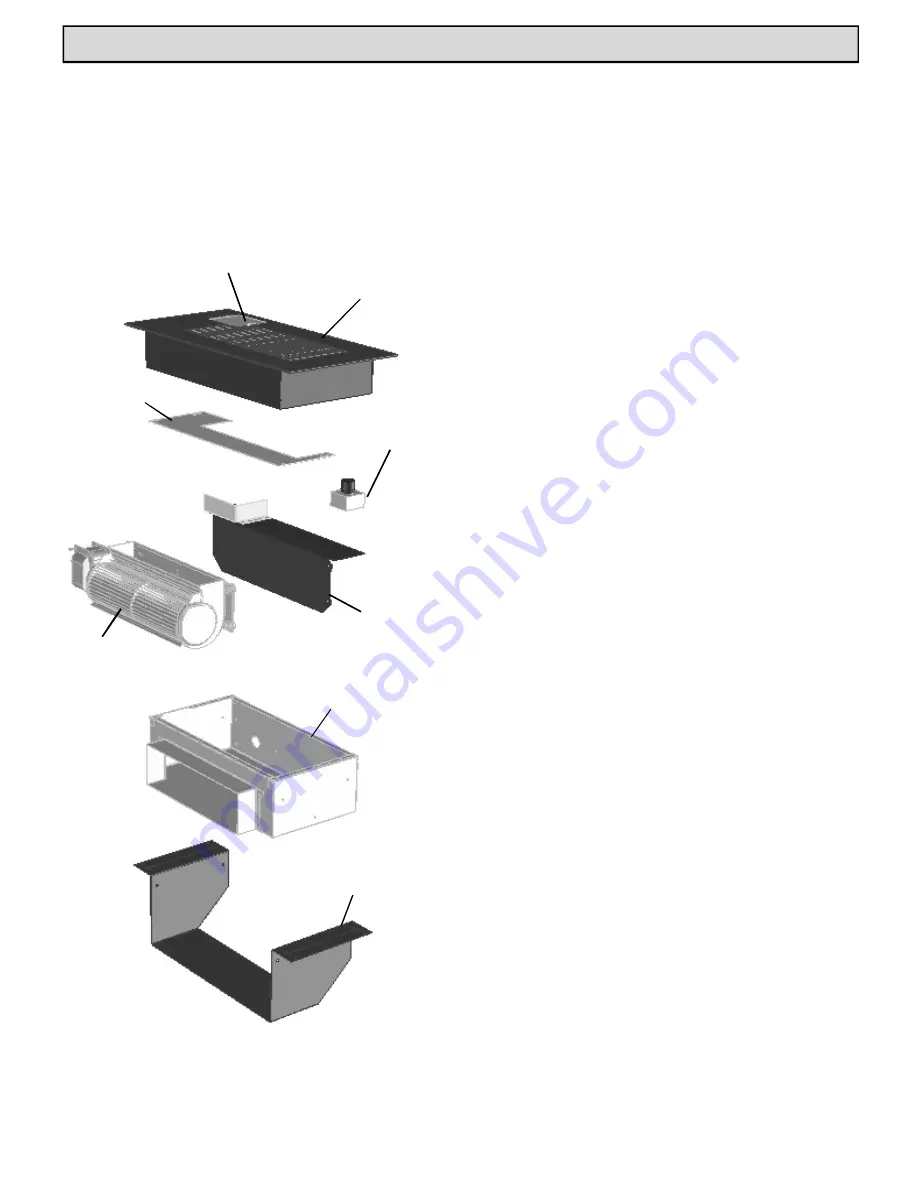

Floor Register

Blower Cover

Speed Control

Blower Mount

Blower Assembly

Blower Box

Floor Mounting

Bracket

Speed Control

Access Door

Floor Register Installation

The difference between the wall register and

floor register is the register itself and the mounting

brackets. The wall register mounts on the wall with

two screws. The floor register mounts in the floor

and is held in place by gravity. The floor register has

a small door to access the blower speed control.