4

Unpacking

The

P61

is

bolted

to

the

skid

to

prevent

move-

ment

during

shipping.

To

free

the

stove

from

the

skid

you

must

re-

move

the

hold-down

bolts

in

the

rear

of

the

pedestal

base.

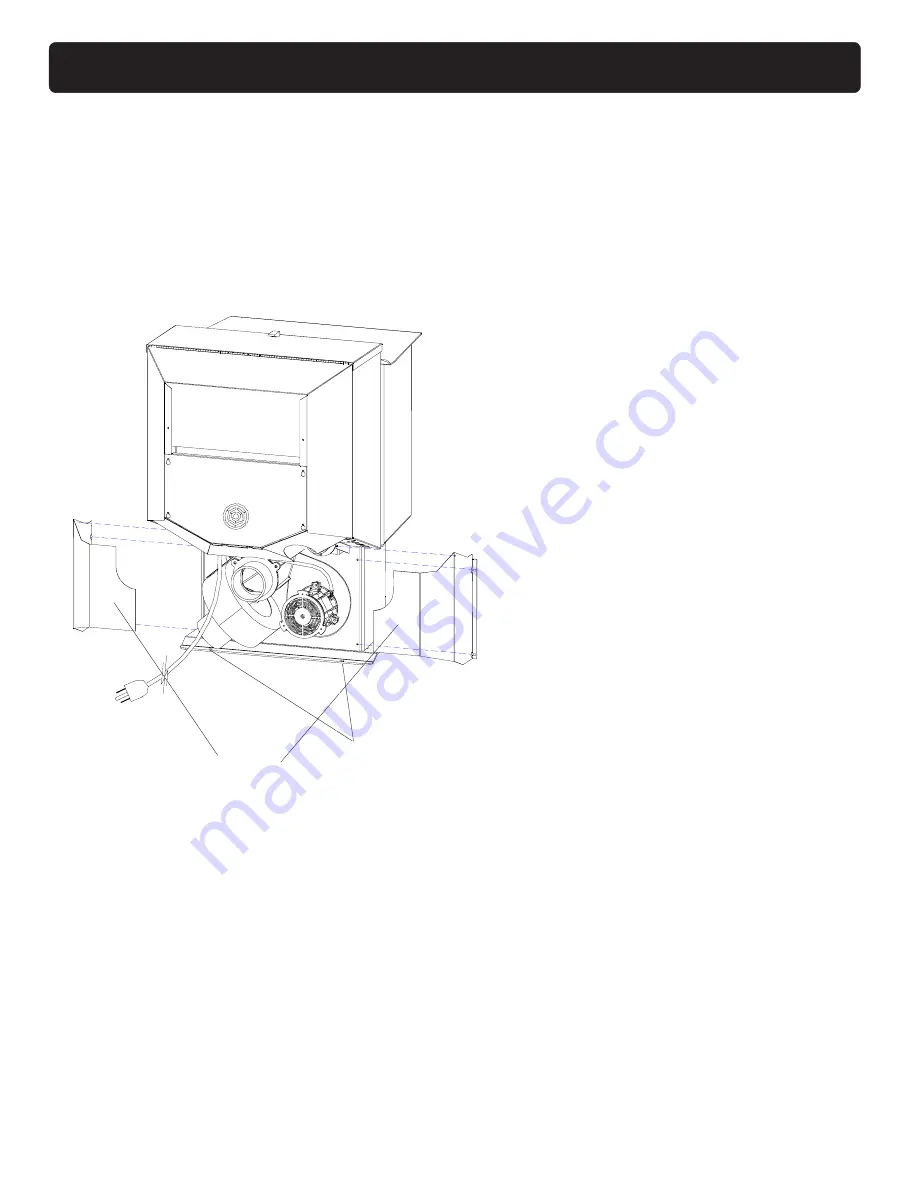

Removing

or

Installing

rear

cover

panels

To

remove

the

rear

cover

panels,

loosen

the

screws

slightly

and

slide

the

covers

outward

as

shown

in

the

illustration.

To

reinstall,

simply

slide

back

into

place

and

retighten

the

screws.

Firebrick

Install

the

firebrick

vertically

on

the

angle

above

the

burnpot.

Flame

Guide

Install

the

cast

iron

flame

guide

on

top

of

the

burnpot

and

make

sure

it

is

fully

seated

against

the

auger

opening.

The

bottom

of

the

flame

guide

is

marked

38+.

Rear

Cover

Panels

Assembly

and

Installation

Shipping

Bolts:

These

holes

are

also

used

for

Mobile

Home

Installation

Fig.

2

Summary of Contents for P61-2

Page 2: ...2 Fig 1 ...

Page 20: ...20 P61 2 Wiring Diagram ...