24

P68 Pellet Stove

Burn Pot Cleaning and Maintenance

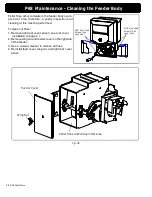

1. Scrape the top holed surface and sides of the burn

pot.(Fig 34) It is not necessary to completely remove

all material from the burn pot. The excess will be pushed

out during the next use.

2. Loosen the (2) wing thumb screws on the lower

front angle of the burn pot. (Fig. 34)

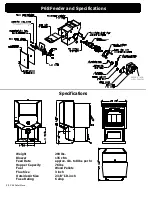

3. Lift off the clean-out cover (Fig.35) to open the bottom

clean-out chamber. (Fig.36)

4. Clean ash buildup from inside the chamber while

cover is off. Use the scraper to tap on the top front

edge of the burn pot. This will help knock pieces of

ash, loosened by the scraping process, down through

the holes. It also helps knock scale off of the igniter

element.

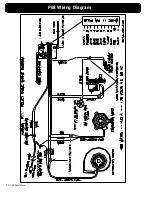

Figure 36

The igniter is made to be removable for service

by insulated male/female wire connectors. These

connections between the hot leads (the wires inside

the burn pot) and the cold leads (the wires from the

control board) are always pulled to the inside rear of

the feeder body.

(Not coiled inside the burn pot.)

It is very important that these connections are

to the inside rear of the feeder body. Also, the extra

wire of the igniter wire service loop must be pulled out

through the rear of the feeder and tied up so that it will

not be damaged by any moving parts.

WARNING

Use caution when cleaning burn pot clean-out

chamber. Do not damage the high temperature

igniter wires.

Fig. 36

DANGER

Disconnect the power to the unit before

removing cover.

Burn pot igniter

Igniter hot lead wires

(high temperature)

Viewed from below through the ash pan opening.

Note: The hot lead/cold lead connection must

always be pulled to the rear of the feeder

body before operation.

P68 Maintenance - Burn Pot

Fig. 35

Fig. 34

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.