29

PF100

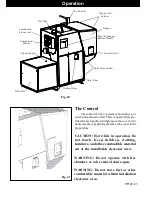

Burnpot cleaning:

The burnpot should be cleaned no less than once a

week. For best operation the burnpot should be cleaned

every time the hopper is filled with pellets. The fire does

not have to be out to scrape the burnpot although it is

recomended the furnace be on minimum burn at the time

of cleaning.

Note:

The furnace can easily be turned to mini-

mum burn regardless of present operation. Simply turn

the Mode Selector to SERVICE. Then turn the Temp

Dial to the #1 setting. If this is done before starting to

refill the hopper the furnace will not be as hot when scrap-

ing the burnpot. When the burnpot cleaning is completed

don’t forget to turn the control back to the Wall Control

positions. See Fig. 61.

Use the flat end of the scraper provided to scrape

down over the holed surface of the burnpot grate. See

Fig. 62. It is not necessary to clean out the scrapings

from this cleaning because they will be pushed out the

next time the auger operates.

Note:

Make a special effort to scrape the bottom

inside corners of the burnpot where the auger tube en-

ters the burnpot. Carbon deposits can build up over time

in this area that may cause a restriction to the flow of

pellets into the burnpot.

Note:

An old long shank screwdriver with the end

sharpened is an ideal aid in the removal of these deposits.

Cleaning the burnpot air chamber:

This area only needs to be cleaned twice a heating

season, unless excessive buildup is noticed during sched-

uled cleanings.

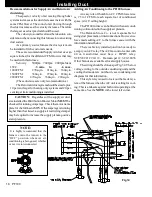

There is a cover on the front of the burnpot to gain

access to the air chamber and igniter. The cover is held

into place by two thumb screws. Loosen the thumb

screws and remove the cover. See Fig. 60. The air cham-

ber can be cleaned of any ash that has fallen through the

holes during operation and cleaning. Also at this time,

remove the feeder assembly cover and remove any fines

that may have accumulated.

Scrape burnpot

to remove any

carbon build-up

that may have

occured.

Scraping can be done while in

operation.

Fig. 60

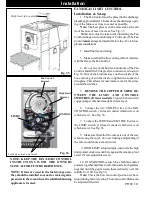

Fig. 61

Fig. 62

Fines cleanout cover

NOTE:

ALWAYS REMEMBER TO CLOSE

THE CLEANOUT COVER AFTER CLEANING.

Feeder Chamber (Fig. 61):

This chamber may get a buildup of fines from the feeder

mechanism movement. This area should be checked and

cleaned at least once a year.

To remove the feeder cover:

• Remove the 5/16" wing nut.

• Slide the cover off of the threaded stud.

• Inspect and clean the inner chamber if necessary. See

Fig. 61.

• Reinstall the cover making certain it is centered on the

feeder body and tighten as tightly as you can by hand.

Possible pellet fines build up area.

Maintenance

Summary of Contents for PF-100 Furnace

Page 11: ...11 PF100 Fig 19 Venting Configuration Graph Venting ...

Page 35: ...35 PF100 Feeder Parts ...

Page 40: ...40 PF100 Testing Label ...