The installation of the ShadowLight XL Fireplace Insert

must conform with local codes, or in the absence of local

codes, with National Fuel Gas Code, ANSI Z233.1 (NFPA

54). Installer l'appareil selon les codes ou règlements

locaux, ou, en l'absence de tels règlements, selon les

Codes d'installation CAN/CGA-B149.

The ShadowLight XL Fireplace Insert may be installed

in mobile homes.

CAUTION: This appliance must be vented to the

outside.

Installation and repair of the ShadowLight XL Fireplace

Insert should be done by a qualified service person.

The appliance should be inspected before use and

at least annually by a qualified service person. More

frequent cleaning may be required due to excessive lint

from carpeting, bedding material, etc. It is imperative

that control compartments, burners, and circulating air

passageways of the appliance be kept clean. Any safety

screen or guard removed for servicing an appliance must

be replaced prior to operating the appliance.

S'ASSURER QUE LE BRÛLEUR ET LE COMPARTIMENT

DES COMMANDES SONT PROPRES. VOIR LES

INSTRUCTIONS D'INSTALLATION ET D'UTILISATION

QUI ACCOMPAGNENT L'APPAREIL.

When operating your Harman ShadowLight XL Fireplace

Insert, respect basic safety standards.

Read these instructions carefully before you attempt

to operate the heater. Failure to do so may result in

damage to property or personal injury and may void the

product warranty.

Consult with your local building code agency and insurance

representative before you begin your installation to

ensure compliance with local codes, including the need

for permits and follow-up inspections.

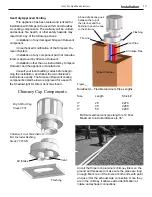

Observing required clearances to combustible materials,

proper connection to an approved venting system, and

the accessibility of the gas and electrical supply must

all be considered when planning the installation of a

ShadowLight XL Fireplace Insert.

Install the ShadowLight XL Fireplace Insert only in

a listed solid-fuel burning factory-built fireplace or

a masonry solid-fuel burning fireplace.

The Fireplace

Insert and vent should be enclosed when installed in,

or when passing through, a living area where children

may come in contact with it.Z21.88-2002-CSA 2.33-

2002,CAN/CGA2.17.

Introduction

• Not for use with solid fuel. Not for use with air filters.

Ne doit pas etre

utilise avec un combustible solide.

• Also for use in mobile (manufactured) homes after home is sited.

• Tested to ANSI Z21.88-2002 / CSA2.33-2002 / CAN-CGA-2.17-M91

• For use with natural gas or propane. A conversion kit, as supplied by the

manufacturer, shall be used to convert this room heater to the alternate

fuel.

Pour utilisation, avec le gaz naturel et le propane. Une trousse de

conversion fournie par le fabricant doit etre utilisee pour passer d’un

combustible a l’autre.

• Keep burner and control compartment clean. See installation and

operating instructions accompanying appliance. S’assurer que le bruleur

et le compartiment des commandes sont propres. Voir les instructions

d’installation et d’utilisation qui accompagnent l’appareil.

•

During repairs or maintenance of this unit, all sealing gaskets or high

temperature silicone seals on the heat exchanger module must be in-

spected for damage and replaced, if necessary, to prevent any leakage

of exhaust into the living areas.

•

Electrical Rating: 115 VAC, 60 Hz, < 1.15 AMP

MANTEL CLEARANCE:

Combustible mantle up to 8” in depth must be

at least 43” above unit base.

CAUTION:

Do not operate the appliance with glass removed, cracked

or broken. Replacement of panel(s) should be done by a licensed or

qualified service person.

CAUTIONNER:

N’orére l’appareil avec le verre enlevé, craque ou casse.

Le remplacement du panneau(s) devrait être fait par une personne de

service qualifie ou autorise.

Manufactured by Harman Stove Company

352 Mountain House Road, Halifax, PA 17032

20 Airport Road, West Lebanon, NH 03784

A LABEL (LOCATED NEAR THE BURNER SYSTEM MOD-

ULE) STATES THE FUEL FOR WHICH THE HEATER IS

EQUIPPED.

SAFETY LABEL

WHI #

This appliance is only for use with the type of gas indicated on the rat-

ing plate and may be installed in an aftermarket, permanently located,

manufactured (mobile) home where not prohibited by local codes. See

owner’s manual for details. This appliance is not convertible for use

with other gases, unless a certified kit is used.

• Homologue Pour Le Canada

• Do not remove this label.

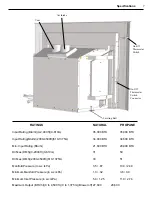

RATINGS

Input Rating(Btu/hr)(0-2000 ft)(0-610m)

Input Rating(Btu/hr)(2000-4500ft)(610-1375m)

Min. Input Rating(Btu/hr)

Orifices (DMS)(0-2000 ft)(0-610m)

Orifices (DMS)(2000-4500ft)(610-1375m)

Manifold Pressure (in w.c./kPa)

Min. Manifold Pressure (in w.c./kPa)

Min. Inlet Pressure (in w.c./kPa)

NATURAL

35,000

34,000

21,600

31

33

3.5/.87

1.3/.32

5.0/1.24

PROPANE

35,000

34,500

20,900

50

51

2.5

3.6/.9

11.0/2.75

CAUTION:

Hot while in operation. Do not touch. Severe burns may

result. Keep children, clothing, furniture, gasoline and other liquids

having flammable vapors away.

ATTENTION:

Les surfaces sont chaudes en service. Ne touchez pas.

Risque de brulure grave. Tenez les enfants, les vatements, le mobilier,

l’essence et autres liquides produisant des vapeurs inflammables B

distance.

Listed Direct Vent Gas Fireplace Heater

Radiateur Ventile

Model: ShadowLight XL Gas Fireplace Insert

4