Harman® • Accentra 52i Owner’s Manual_R19 • 2013 -___ • 03/16

14

3-90-00574c

The Accentra 52i Pellet Insert is more than just automatic

ignition, it is also automatic temperature control. The

automatic system will allow the fire size to be adjusted

to match the heating needs and even put the fire out if

necessary. If heat is needed after the fire is out, the Pellet

Insert will automatically re-ignite and adjust the fire size to

match the heating need. The totally automatic room sensor

mode is recommended because of its efficiency. The unit

can be switched between "AUTO" and "MANUAL" at any

time during operation.

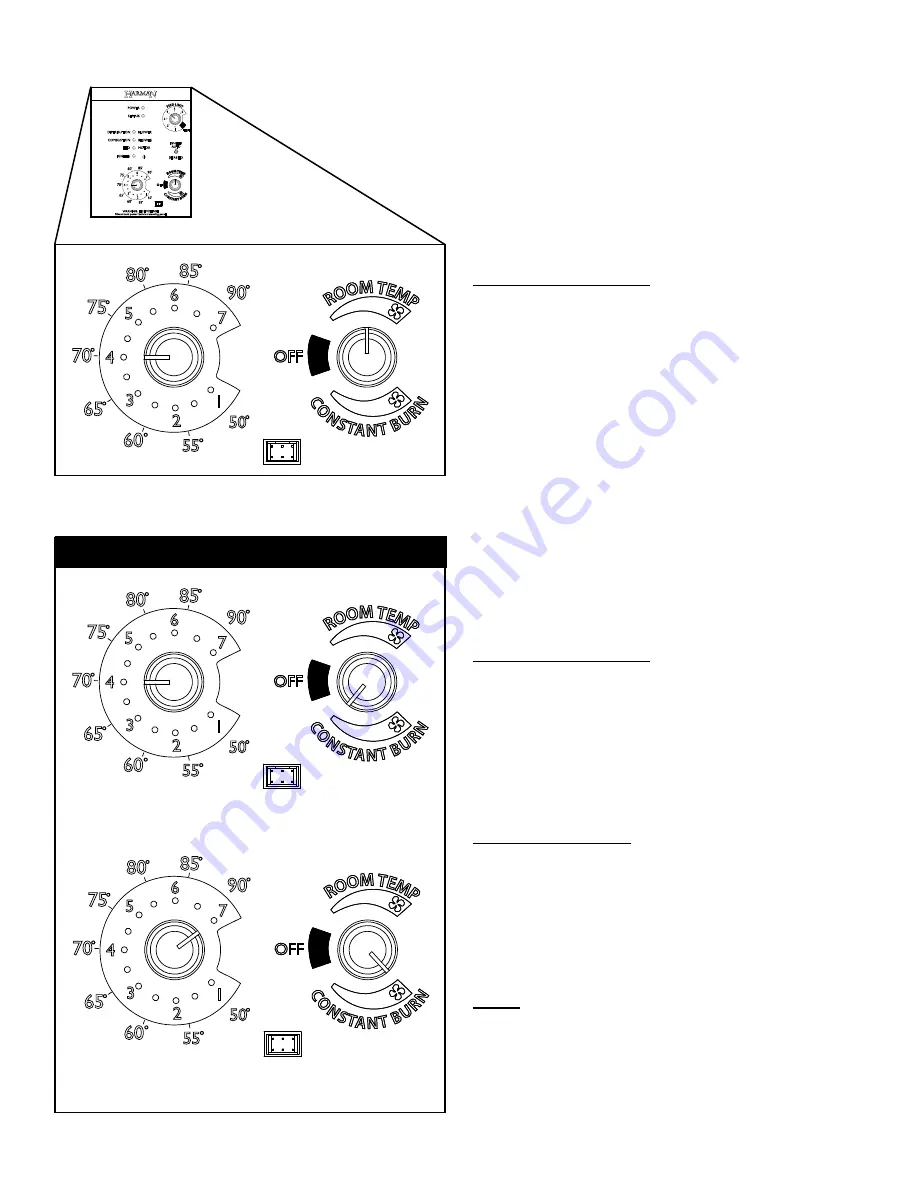

Igniter switch to “AUTO”

Room Temperature Mode

In “Room Temp Mode” heat output is controlled automatically

by the Room Sensing Probe. When the Room Sensing Probe

calls for heat, the stove will increase output. When the Room

Sensing Probe is getting close to the set temperature, the

stove will begin to level off output and keep the fire burning

at just the right temperature to maintain that setting.

High output is determined by the feed rate setting. This

setting, generally on #4, can be increased if higher burn rates

are necessary (Figure 4.6). The unit’s maximum burn rate

should not create less than 1” of ash on the burn pot front

edge (Figure 4.7). Overfeeding is not a safety concern, but

fuel may be wasted if unburned pellets fall into the ash pan.

In “Room Temp Mode” a constant fuel consumption rate is

sacrificed for exact room temperature. Therefore, as it gets

colder more pellets will be burned automatically.

The distribution blower speed will vary according to the

position of the mode selector pointer and fire size.

Igniter switch to “AUTO”

Stove Temperature Mode

This allows for automatic ignition upon start-up only. The unit

can then be set at any desired setting. The heat output and

fuel consumption will remain constant regardless of room

temperature. The unit’s maximum feed rate should not create

less than 1” of ash on the burn pot front edge. Figure 4.7.

The unit’s low burn or maintenance setting is as low as it will

go. It will not go out unless it runs out of fuel or is turned off.

Shut-Down Procedure

To kill the fire or stop burning the stove, turn the Mode

Selector to “OFF”. This will cause the fire to diminish and

burn out. When the fire burns out and the stove cools down

everything will stop.

If you pull the plug to shut down the stove, all motors will stop.

This may cause incomplete combustion and smoke in the

firebox. If the load door is opened, the smoke may escape.

NOTE:

At the end of the season the best way to shut down

the stove is simply let it run out of pellets, then the stove will

shut down automatically.

Room Temperature Mode:

This setting will produce a room

temperature of 70 degrees with the distribution blower at medium

speed.

This setting will produce medium heat with the distribution

blower on "low".

This setting will produce continuous maximum heat output with

the distribution blower at full speed.

Stove Temperature Mode

E. Automatic Ignition

(Continued)