25

Save These Instructions 3-90-798 Dry Seasoned Wood Only!

Oakleaf Woodburning stove

3. grates

The Harman Oakleaf's unique grate system

consists of one

flat bottom grate, and two front

andirons. The bottom grate has slots which

allow the ash to fall into the ash pan by passing

a poker back and forth across the grate. The

andirons keep the fuel from coming into direct

contact with the glass, and keep hot coals and

embers from spilling out while reloading. Never

build a fire directly against the glass.

The grates and andirons must remain

in place at all times. do not tamper with

or change the configuration of this grate

system.

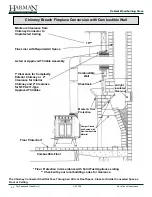

SECONDARY AIR

THRU BRICK

SECONDARY AIR FLOW

SECONDARY AIR ENTERING

EXHAUST STREAM

SECONDARY AIR THRU

RAMP BRICK

EXHAUST STREAM

PRIMARY AIR FLOW

PRIMARY & SECONDARY AIR FLOW

C. The Combustion process

Combustion in the Harman Oakleaf is precisely

controlled and is best explained in two parts.

During a wood fire, combustion air enters at the

bottom front of the stove where it travels upward through

channels at either side of the front door. From the

manifold located above the front door, it is directed into

the firebox as a sheet of air flowing between the glass

and the wood. This concept helps to keep the glass

clean, while providing the oxygen needed to sustain

burning. This is what is known as "Primary Combustion".

Additional air enters at the bottom rear of the stove

body. Some of this air enters through holes in the rear

bricks where it is used to revitalize the fire at the rear

of the firebox. The remainder is delivered into the

"Firedome" combustion package where the "Secondary

Combustion", or re-burning of the smoke, occurs.

During combustion, the burning of wood proceeds

through several stages. The initial or evaporation stage

is where the moisture in the wood is driven off in the

form of steam. A second stage is where the volatile

gases contained in the wood are released and burned.

This represents most of the wood's heating capacity.

The final stage is the charcoal stage where the charcoal

burns the remaining heat content in the wood fuel. Ash

remains after the burning is complete. Within the primary

firebox two or more of these stages of combustion are

occurring at once.

Always be sure to provide adequate ventillation

to the room where the apliance is located, to prevent

air starvation. In tight construction, consider installing

outside air to the appliance.

2. doors

Your stove has a large glass-paneled door for loading

and fire viewing, a separate smaller door for removing

ashes and a top loading door.

Front Door

Before opening, always check for wood, embers, or

ash that may be ready to fall out of the door.

To open the glass door, open the bypass damper

first, then turn the handle clockwise and pull out; to

close the door, push the door closed with the handle

in the open position, then turn, counter-clockwise, to

engage the latch.

Ash Door

To open the ash door, lift up the handle and pull out.

Close the door by pushing in and pushing the handle

all the way down.

Top Load Door

To open the top load door, open the bypass damper

and then lift to open the top load door.

All doors must be closed while the stove is in normal

operation, and the gaskets routinely examined for wear

and replaced when necessary. Good door seals are

important for maintaining control of the stove. Never

operate with the ash door open. Operating the stove with

the ash door open, or with a door inadequately sealed,

could create a serious overfiring condition (discussed

later in this section).

The glass used in your Oakleaf is manufactured

to exact standards to withstand the high heat of the

fire, but like all glass, it must be treated with common

sense and care. Never abuse the glass by slamming

the door shut or striking the glass with a heavy object.

If the glass is broken or damaged, do not operate the

stove until it has been replaced

(See instructions in the Maintenance section.)

Summary of Contents for OAKLEAF 1-90-797000

Page 39: ......