Oakleaf Woodburning Stove

Dry Seasoned Wood Only!

Harman® • Oakleaf Owner's Manual_R23 • 2010 -___ • 09/15

12

3-90-798

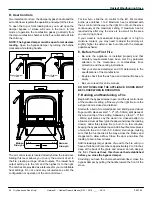

C. Floor Protection Requirements

Floor Protection Requirements

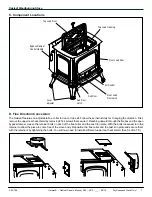

If the Oakleaf is being installed on a combustible floor, the

bottom heat shield (part # 1-00-797058) must be installed

with a suitable material for floor protection. (See Section

7F). This heat shield is supplied with the unit and must be

installed. Floor protection must be at least 3/8 "(9.5 mm) thick

insulating material having a value equal to or greater than

0.84k/in. (The higher the value of k, the better the protection.)

Another method for calculating floor protection is in R value.

This requirement would be for an R value of 0.89 or higher.

(The higher the R value, the better the protection).

In all installations, the area under and around the stove must

be protected from falling ash and live coals.

The area under a

horizontal run of chimney connector must also be protected,

extending two (2) inches beyond the measurement of the

horizontal connector.

Further guidelines for floor protection are as follows:

In the U.S. the floor protector must be completely under the

stove, and extending 18" in front of the door opening, 8" to

each side and 8" to the back.

In Canada, the floor protection must extend 18" (457mm)

in front of the door opening, 8" (203mm) to each side and

extend to the wall behind the stove.

Minimum Size floor protection (USA) is 42-3/4" Deep by 32-

5/8" Wide.

Floor protection touching the wall: 53-3/8" Deep x 32-5/8"

Wide.

DANGER:

The appliance legs may not be removed for

installation.

Minimum Size floor protection (USA) is 32-5/16" Wide By

43-3/8" Deep.

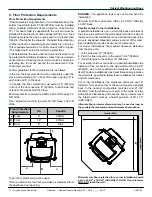

Parallel versus Corner Installations

A parallel installation is one in which the back and sides of

the stove are parallel to the walls behind and to the side of

the stove. A corner installation is one in which the back of the

stove is positioned diagonally across a corner of the room.

Each installation requires its own set of clearances.

For corner installations, the required clearance distances

from the stove are:

1. to the side wall, 14" (356mm).

2. From the flue connector to the wall, 21-3/4" (552mm)

3. Horizontal pipe to the ceiling, 16" (406mm).

For a vertical chimney connector in a parallel installation the

distance of the connector to the side wall must be 26-3/4"

(679mm), due to the required side clearance of the stove

itself. Fireplace installations must meet these same clearance

requirements; specifically follow these guidelines for mantel

and trim clearances.

For corner installations, the clearance distances are 14"

(356mm) from each corner of the stove measured straight

back to the nearest combustible material, and 21-3/4"

(552mm) from the chimney connector to the walls. To stay

within these clearances and have the floor protector touch

the interior wall it must be a hearth pad size of 53" x 53"

(USA ONLY).

Alternate floor protector dimension may be used as long as

they satisfy the measurement requirements shown above.

Type II floor protection must be used.

*Floor protection for the front and sides as measured from

the appliance door opening.

60”

60”

Interior Wall

Interior W

all

Minimum size floor protection for a corner installation hearth

pad is 43-3/8" x 32-5/16" (USA ONLY). NOTE: Floor protector

WILL NOT touch the wall.

J

J

K

L

Floor Protection

Requirements

US

Canada

J

Sides

8"

203mm

K

Front

18"

457mm

L

Rear

8"

Wall