Harman® • P43 Installation Manual_R23 • 2008 -___ • 04/14

16

3-90-04301i

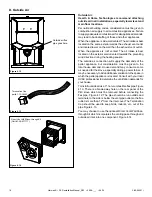

Outside air flex

pipe goes here.

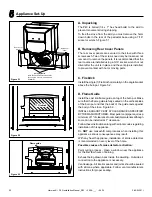

Outside Air:

Hearth & Home Technologies recommend attaching

outside air in all installations, especially lower level and

main floor locations.

Per national building codes, consideration must be given to

combustion air supply to all combustion appliances. Failure

to supply adequate combustion air for all appliance demands,

may lead to back-drafting of those and other appliances.

When the appliance is side-wall vented: The air intake is best

located on the same exterior wall as the exhaust vent outlet

and located lower on the wall than the exhaust vent outlet.

When the appliance is roof vented: The air intake is best

located on the exterior wall oriented towards the prevailing

wind direction during the heating season.

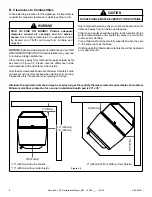

The outside air connection will supply the demands of the

pellet appliance, but consideration must be given to the

total house demand. House demand may consume some

air needed for the stove, especially during a power failure. It

may be necessary to add additional ventilation to the space in

which the pellet appliance is located. Consult with your local

HVAC professional to determine the ventilation demands for

your house.

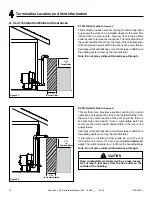

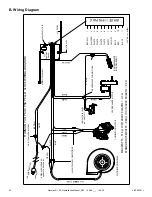

To install outside air use 3". non-combustible flex pipe Figure

4.13. There is a break-away hole on the rear panel of the

P43 stove which must be removed before connecting the

flex pipe. Figure 4.12. The pipe should be run outside and

terminate to the side or below the vent pipe outlet so the flue

outlet is more than 12" from the inlet cover. The Termination

Cap should be used to keep birds, rodents, etc. out of the

pipe Figure 4.13.

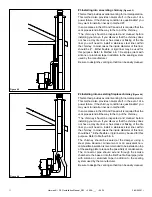

You may choose to use the optional Direct Vent Wall Pass-

through Kit which incorporates the venting pass-through and

outside air inlet into one component. Figure 4.14.

Direct Vent Wall Pass-through Kit

(Part #1-00-677177)

D. Outside Air

Figure 4.12

Figure 4.14

Termination Cap

part# 1-10-09542

Figure 4.13