3-90-05822R29_JR15_04/14

"PReVeNT HOUSe FIReS"

Install and Use Only in

Accordance With Manufacturer's Installation and Operation Instructions.

Contact Local Building or Fire Offi

cials

About Restrictions and Installation Inspection in

Your

Area.

W

ARNING :

THE STRUCTURAL

INTEGRITY

OF

THE MANUF

ACTURED HOME FLOOR, W

ALL,

AND CEILING/ROOF MUST

BE MAINT

AINED. DO NOT

INST

ALL

IN SLEEPING ROOM.

An

outside

combustion

air

inlet

must

be

provided.

Combustion

air

should

not

be

obstructed.

Refer

to Manufacturer

’s instructions

and local codes regarding the requirements for passing the exhaust

venting system through a combustible wall or ceiling.

Inspect and Clean Exhaust V

enting System Frequently

.

Use a 3" or 4" diameter type "L" or "PL" venting system.

Do Not Connect

This Unit to a Chimney Flue Serving

Another

Appliance.

FOR USE WITH WOOD PELLET

FUEL

OR UP

T

O 50% CORN / PELLET

MIXTURE ONL

Y.

The Use of Other Fuels May Create an Unsafe Condition.

Input Rating Max: 5.5 lb. fuel/hr

.

U.S. Electrical Rating: 1

15 V

AC, 60 Hz, Start 4.2

AMPS, Run 2.8

AMPS

Route Power Cord

Away From Unit.

dANGeR:

Risk of Electrical Shock. Disconnect Power Before Servicing Unit.

For Further Instruction, Refer

To Owner's Manual.

Replace glass only with 5mm ceramic available from your dealer

.

Keep V

iewing and

Ash Removal Doors

Tightly Closed During Operation.

dO NOT ReMOVe THIS LABeL

/ Ne P

AS eNLeVeR CeTTe ÉTIQUeTTe

Report #/ Rapport #135-S-22-4, 135-S-22b-6.2 Tested to /

Testé à:

ASTM E 1509-04, ULC/ORD-C1482-M1990, ULC-S627-00

Made in U.S.A. of US and imported parts. / Fabriqué aux États-Unis-d’Amérique par des pièces d’origine américaine et pièces importées.

"PReVeNTION deS INCeNdIeS"

Respecter scrupuleusement les instructions du constructeur pour l'installation et les consignes de fonctionnement. Respecter les règles de sécuritè en vigueur dans votre région.

AVeRTISSeMeNT POUR MOBILe HOMeS:

Ne pas installer dans une chambre. ll est imperatif

de prévoir une prise d'alr extérieur

. L'intégrité structurale du plancher

, du plafond et des murs doit étre

strictement préservée. Se reporter aux instructions du fabricant et aux réglementations spécifi

ques

locales concernant les précautions requises lors de la traversée d'un mur ou d'un plafond. Contróler et nettoyer fréquemment tout le systeme d'evacuation des fumées conformément aux recommandations du constructeur

. Utiliser des tuyaux <<Spécial granulés>> de Ø76 mm ou

102 mm. Ne pas raccorder ce poéle à un conduit de cheminée déjà utilisé pour un autre appareil.

FONCTIONNe eXCLUSIVeMeNT

AVeC deS GRANULeS de BOIS

.

Appareil de chauf

fage à granulé type. Consommation maximum: 3.63 kg/h.

US coupure: 1

15 V

AC, 60 Hz, 4.2 amps Démarrer

, Exécuter 2.8

AMPS

Tenir le cordon d'alimentation à l'écart du poèle.

dANGeR:

Risque d'électrocution. Débrancher l'appareil avant toute intervention.

Ne remplacer la vitre qu'avec une vitre céramique 5mm de méme qualité disponible auprès de votre revendeur

.

Pour une information plus compléte, se reporter à la notice d'utilisation.

Tenir la porte

hermétiquement close durant fonctionnement. Ne faites pas obstacle l’espace sous le réchauf

feur

. T

oujours fournir un approvisionnement suffi

sant en air frais

jusqu’au lieu d’installation

Appliance

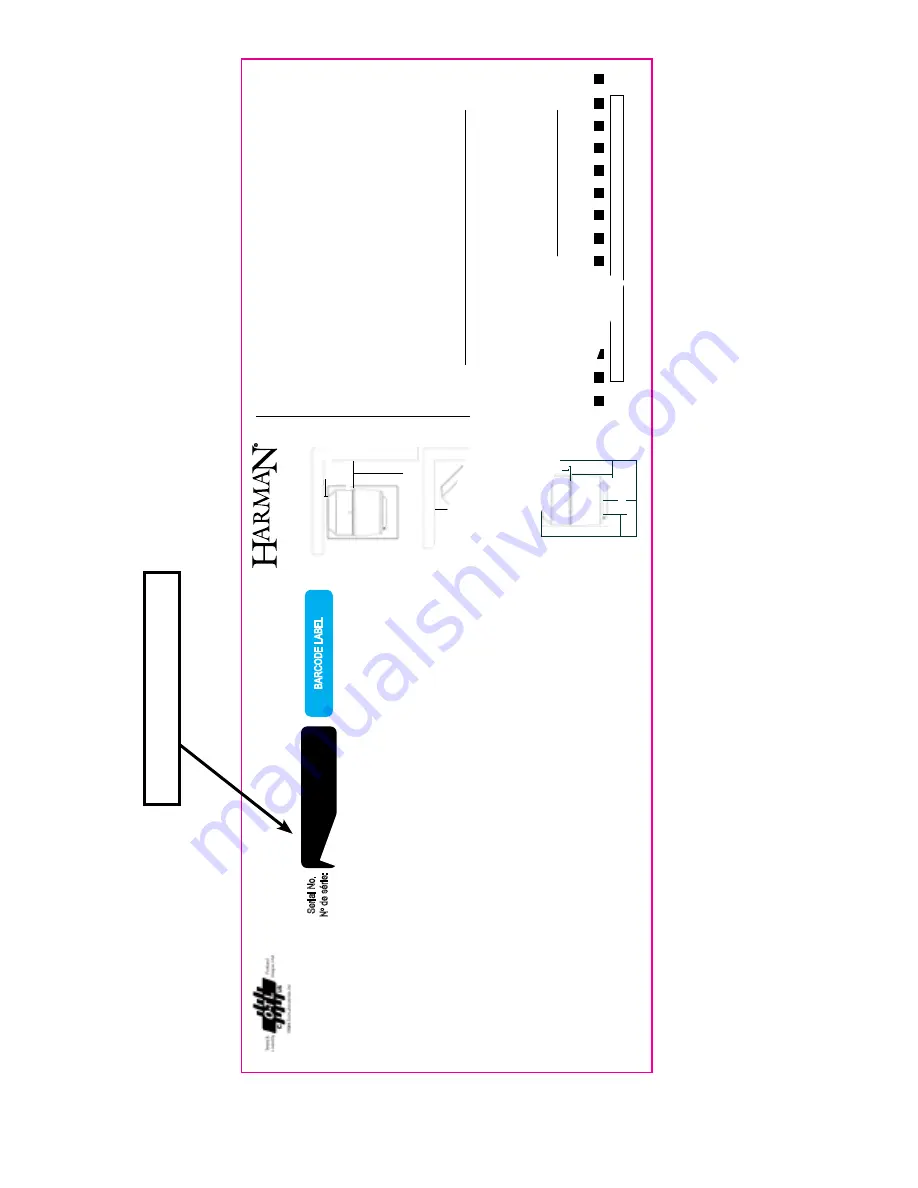

MOdeL

/ Modéle: “P61A”

Room Heater Pellet Fuel Burning

Type. Suitable for Mobile-Home Installation.

Appareil de chauf

fage à granulés de bois Conçu pour maisons mobiles

2"(51mm)

12" (305mm) with side shields 18" (457mm) w/out side shields

9”(228mm) 13”(330mm)

9"(228mm)

13”(330mm)

BARCODE LABEL

MINIMUM CLEARANCES

TO COMBUSTIBLES/

DIST

ANCES DE SECURITE P

AR RAPPOR

T AUX

MA

TERIAUX COMBUSTIBLES:

Back W

all / Entre Mur

Arrière

2”/ 51mm

2”/ 51mm

Side W

all / Entre Paroi Latér

18”/ 457mm

12”/ 305mm

CORNER INST

ALLA

TION / EN

ANGLE

W

alls to

Appliance

13”/330mm

9”/228mm

Entre Murs et appareil Flue Connector/Raccord à la cheminée 1” /25mm

FLOOR PROTECTION / Protection Du Plancher

USA

Canada

Sides*/

Côtés

(A) 6”

200mm

Back**/

Arrière

(B) 6”

200mm

Front*/

Avant

(C) 6”

450mm

**Measured from pedestal base in the US ONL

Y

**Mesuré à partir de la base du socle aux États-Unis uniquement *Measured from Glass Opening *Mesurer à partir de la surface de la porte en verre

Floor Protection Must Be a Non-Combustible Material. Must

Also

be

Place

Under

Any

Horizontal

Flue

Connector

,

Extending 2” or 51mm Beyond the Pipe Measurement. Pour

protéger

le

plancher

, il

faut

sous

le

pêole

un

matériau.

Qui

doit

aussi

être

placé

sous

les

parties

horizontales

du

tuyau

de

raccord

à

la

cheminée

et

s’étendre

à

51mm

o

2

po.

au-delà

de

la mesure du tuyau.

WITHOUT

SIde SHIeLdS

WITH

SIde SHIeLdS

Sans Écrans

Latéraux

Avec Écrans

Latéraux

Harman P61A

Pellet Stove

Black Background with bare metal for print-adhesive backed, metal plate.

a

a

c

b

usa

canada

F

loor

protect

or

Protection de sol Floor Protection

008

Serial No. N

o

de série:

rev e

P.n. 3-90-08626

10-3/4"

4-3/8"

date of Manufacture / date de fabrication:

2013 2014 2015 jan Feb Mar

aPr Ma

Y jun jul

aug seP

oct nov dec

Fabriqué par: Hearth and Home T

echnologies 352 Mountain House Road, Halifax P

A 17032

US eNVIRONMeNT

AL

PROTeCTION

AGeNCY

This

appliance

complies

with

Canadian

Standards

Association

(CSA)

B415.1

and

Title

40

of

the

U.S.

Code

of

Federal

Regulations,

Part

60,

SubPart

AAA.

This

model

is

exempt

from

EP

A certifi

cation under 40 CFR 60.531 by defi

nition [W

ood Heater (A) “air-to-fuel ratio”].

Cet

appareil

est

conforme

a

l’Association

Canadienne

des

Standards

(CSA)

B415.1-10,

clause

4 et

Titre

40

du

Code

des

Régulations

Fédérales

des

États-Unis,

partie

60,

section

AAA.

Ce

modèle

est

exempt

de

la

certifi

cation

EP

A

sous

40

CFR

60.531

par

défi

nition

(Appareil de chauf

fage au bois (A) “ ratio

Air-Combustible).

2

P61A Pellet Stove

The Label Pictur

ed Is For

Refer

ence Only

. For

specific infor

-

mation r

egarding testing and clearances, consult the actual

label on the r

ear

of the stove.

Ple

ase

copy

your

seria

l numb

er

from

the

la

bel

on

your

stove

to

the

box

below

.

serial

n

u

M

ber