3

Installing the Vehicle Wiring Harness

Important Note: IMPROPER WIRING IS THE #1 CAUSE OF PROBLEMS IN THE OPERATION OF

A VEHICLE LIFT. FOLLOW THE WIRING INSTRUCTIONS CAREFULLY

Located in the hardware package is the vehicle wiring harness. The harness is manufactured to, and

complies with the SAE J1128 requirements. The wire harness is approximately 23 ft. long and will

accommodate most vehicles.

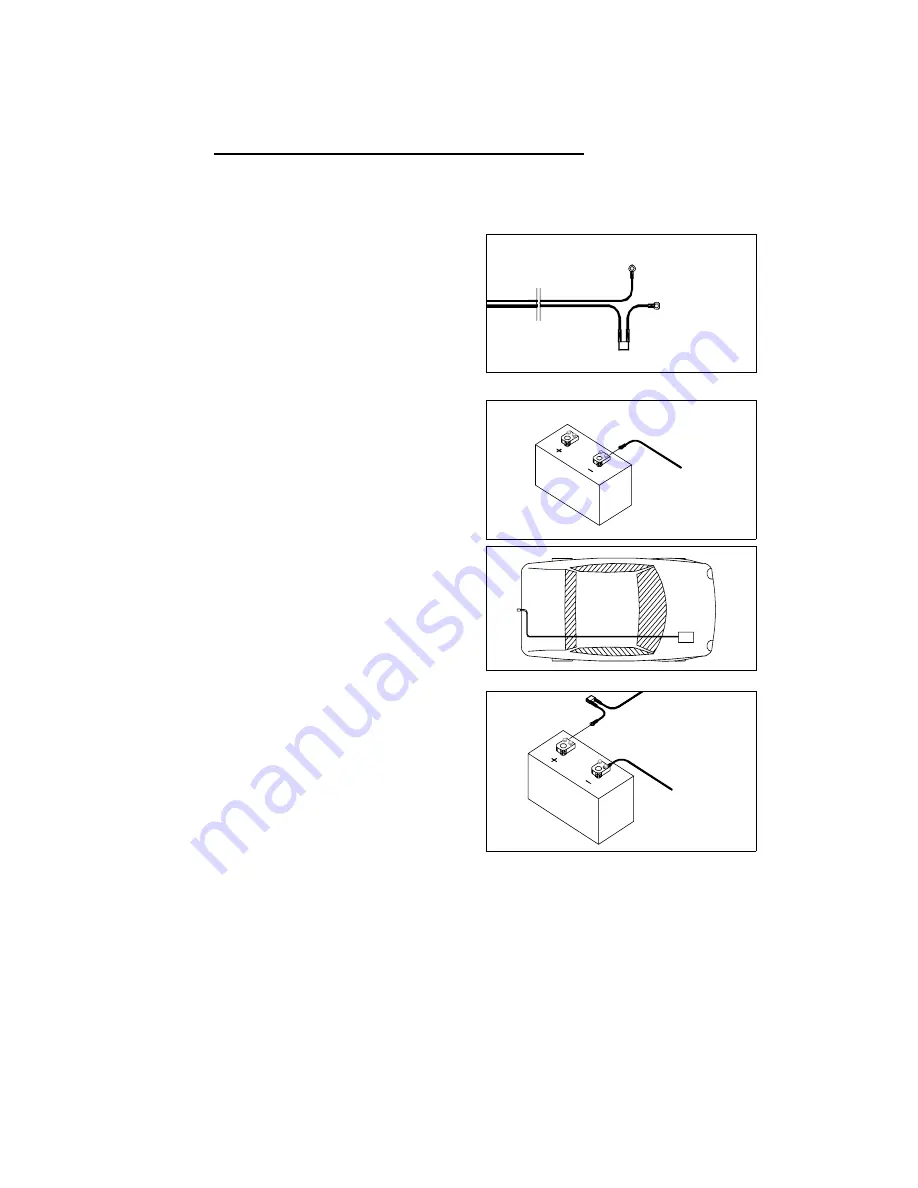

1. Unwind the harness and lay it flat. One end of the

harness has a black plug. This is the lift end of the

harness and goes to the back of the vehicle.

2. Begin routing the wiring harness at the vehicle

battery. Attach the black wire to the negative

terminal on the battery.

Do not attach the red

wire yet.

3. Run the wiring harness under or when possible

through the vehicle, back to the trailer hitch.

Always locate the wiring harness where it can not

be snagged by road debris and away from the

vehicles gas tank.

4. If the harness is too long for the vehicle, coil the

excess wire and secure it to the vehicle frame with

the supplied tie wraps.

Do not cut or shorten the

harness.

Secure the plug about even with the end

of the hitch receiver tube.

5. Attach the red wire to the positive terminal on the

battery.

Important Reminder: Never attempt to attach the wire harness to a secondary power source.

The lift requires direct connection to the battery.

Caution:

When the installation requires the wiring harness be run on the underside of a

vehicle, route the harness away from the exhaust system, brake lines, fuel lines, gas tank,

p

inch points, and sharp edges. Locate the wiring harness where it can not be snagged by

road debris.

Manufacturer’s Recommendation: Schedule a routine maintenance visit with the end user.

Harmar recommends the lift be greased in the applicable areas, and the wire harness

connections be checked for corrosion, and/or decay, as such conditions are normal due to

environmental changes.