B=BLACK,

A=RED

IMPORTANT NOTE:

IMPROPER WIRING IS THE #1 CAUSE

OF PROBLEMS IN THE OPERATION OF A VEHICLE LIFT.

FOLLOW THE WIRING INSTRUCTIONS CAREFULLY

BLACK WIR

E

SIDE MOUNT

BLACK

WIRE

OR

OR

TOP MOUNT

WIRING THE VEHICLE

TO BATTERY

END

CONNECTOR

LETTERS ARE

MOLDED INTO

PLASTIC

HINGED

RETAINER

A

B

BLACK WIR

E

RED WIRE

Protectiv

e

tubing

CORRECT

ADJUST BY

PRYING OUT

SLIGHTLY

IF NEEDED

PROBING FOR 12 VOLTS MAY INDICATE

A CONNECTION, BUT NOT NECESSARILY

A SUFFICIENT CONNECTION.

THE LIFT’S MOTOR CAN DRAW UP TO

30 AMPS AT SOME POINTS, REQUIRING

ALL OF THE AVAILABLE

TO FLOW

PROPER CURRENT. POOR CONNECTIONS

ARE THE #1 PROBLEM ASSOCIATED WITH

A SLOW, WARM, POORLY PERFORMING MOTOR.

NOT ONLY WILL THE MOTOR PERFORM POORLY,

BUT WILL PREMATURELY DETERIORATE.

IF A SINGLE STRAND OF A MULTI-

STRAND WIRE IS MAKING CONTACT,

12V WILL APPEAR ON THE METER, OR TEST LIGHT,

BUT WILL NOT ALLOW THE MOTOR TO OPERATE.

IT IS ALWAYS BEST TO TEST BOTH

CURRENT AND VOLTAGE, OR RUN THE MOTOR

WITH KNOWN GOOD SHOP BATTERY OR POWER

SOURCE WHEN TROUBLESHOOTING.

WIRE

WHEN THE INSTALLATION

REQUIRES THE WIRING

HARNESS BE RUN ON THE

UNDERSIDE OF THE VEHICLE,

ROUTE THE HARNESS AWAY

FROM THE EXHAUST SYSTEM,

BRAKE LINES, FUEL LINES< GAS

TANK, PINCH POINTS, AND SHARP

EDGES. LOCATE THE WIRING

HARNESS WHERE IT CAN NOT

BE SNAGGED BY ROAD DEBRIS

RED WIRE

RED WIRE

OR

LAST

NEVER ATTEMPT

TO CONNECT

THE HARNESS

TO A SECONDARY

POWER SOURCE.

ALWAYS CONNECT

BOTH LEADS

DIRECTLY TO THE

BATTERY

20 AMP

SELF

RESETTING

CIRCUIT

BREAKER

SEALS

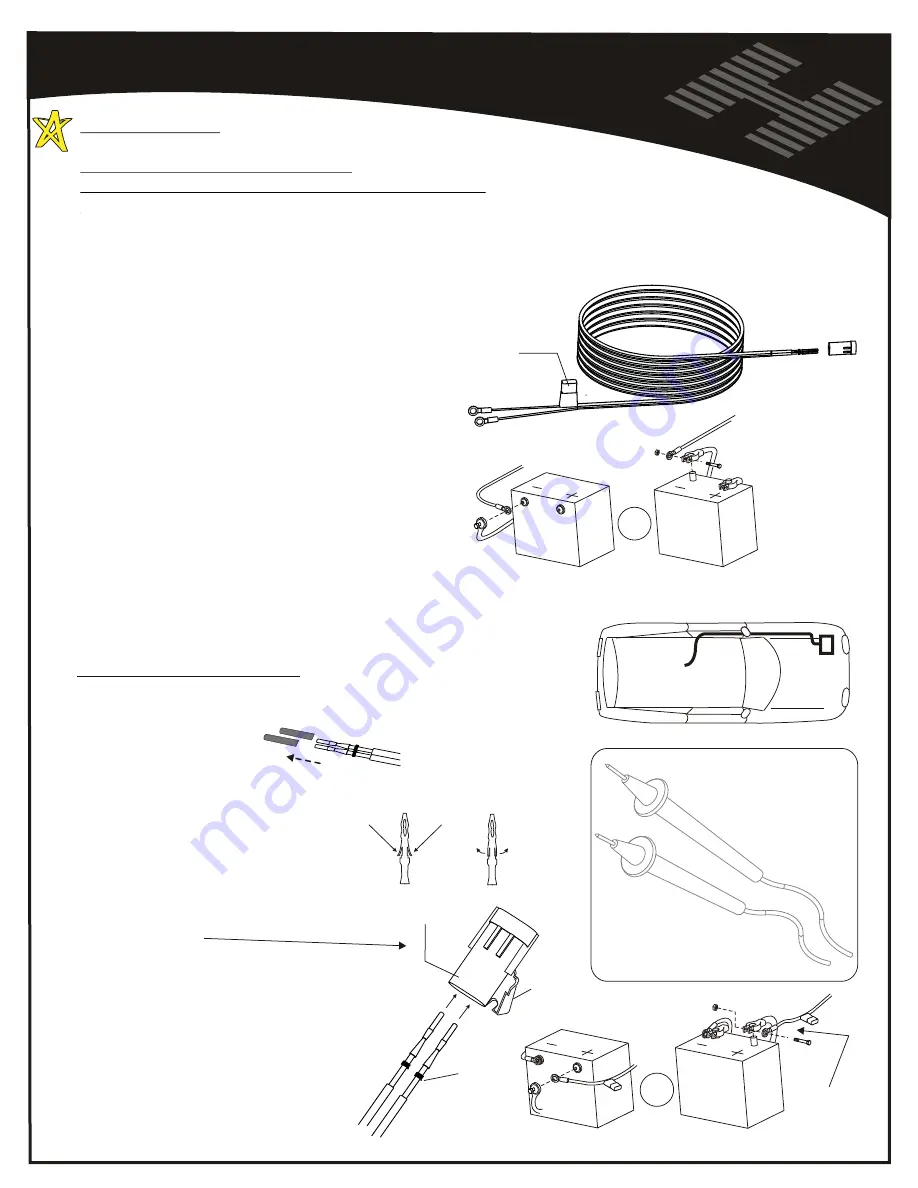

LOCATED IN THE HARDWARE PACK IS THE VEHICLE WIRING HARNESS. THE HARNESS IS MANUFACTURED TO, AND COMPLIES WITH, THE

SAE J1128 REQUIREMENTS. THE WIRE HARNESS IS APPROXIMATELY 23 ft LONG AND WILL ACCOMMODATE MOST VEHICLES.

YOUR HEAVY DUTY HARNESS HAS BEEN LEFT UN-ASSEMBLED

FOR EASE OF INSTALLATION. THE END CONNECTOR HAS BEEN

INCLUDED SEPARATELY FROM THE HARNESS TO ALLOW

THE INSTALLER TO THE RUN THE WIRE UNDER AND THROUGH

THE VEHICLE WITH THE SMALLEST HOLE POSSIBLE. FOLLOW

THESE INSTRUCTIONS TO ASSURE PROPER INSTALLATION.

UNWIND THE HARNESS AND LAY IT FLAT.

ONE END OF THE HARNESS HAS 2 COVERED PINS.

THIS IS THE LIFT END OF THE HARNESS AND

GOES TO THE MIDDLE OF THE VEHICLE AND INSIDE

TO THE REAR CARGO AREA.

BEGIN ROUTING THE WIRING HARNESS AT THE VEHICLE BATTERY.

ATTACH THE BLACK WIRE TO THE NEGATIVE TERMINAL ON THE BATTERY.

DO NOT ATTACH THE RED WIRE UNTIL THE END.

RUN THE WIRING HARNESS UNDER OR WHEN POSSIBLE THROUGH

THE VEHICLE, BACK TO THE REAR CARGO AREA. ALWAYS LOCATE

THE WIRING WHERE IT CAN NOT BE SNAGGED BY ROAD DEBRIS AND

AWAY FROM THE GAS TANK.

THROUGH THE VEHICLE IS BEST FOR THE AL-600 SERIES, GAINING ENTRY

INTO THE VEHICLE THROUGH THE FIREWALL. HOWEVER IF YOU WISH

TO RUN THE HARNESS UNDER THE VEHICLE, A HOLE WILL MOST LIKELY

NEED TO BE DRILLED TO GET THE WIRE INTO THE REAR CARGO AREA.

IF THE HARNESS IS TOO LONG FOR THE VEHICLE, COIL THE

EXCESS WIRE AND SECURE IT TO THE VEHICLE FRAME

WITH SUPPLIED TIE WRAPS.

DO NOT CUT OR SHORTEN THE HARNESS.

ONCE THE HARNESS IS RUN INTO

THE VEHICLE, REMOVE PIN’S

PROTECTIVE TUBING.

INSPECT THE PIN’S RETAINING FLANGES.

THE MAY HAVE BECOME DEFORMED

WHILE RUNNING THEM THROUGH THE VEHICLE.

THESE ARE CRITICAL TO SECURE THE PINS INSIDE

THE END CONNECTOR. ADJUST AS NEEDED.

FLIP OPEN END CONNECTOR’S HINGED RETAINER.

INSERT PINS AS SHOWN:

VERIFY THE WIRES CAN NOT BE PULLED OUT

BY MODERATELY PULLING ON WIRE.

BE SURE WIRE SEALS ARE INSIDE CONNECTOR,

AND CLOSE THE END CONNECTOR’S HINGED RETAINER.

PLUG CONNECTOR INTO LIFT

LAST: ATTACH RED WIRE TO THE POSITIVE

TERMINAL ON THE BATTERY

SIDE MOUNT

TOP MOUNT

3