9

helix curved Stair lift - Installation & Service Manual 2014

Part Number: 630-00008- Rev A

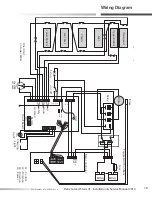

Wiring & chassis

13.

Install batteries.

14.

connect battery wire.

[Figure 9-1]

15.

Replace Shroud

Figure 9-2

Figure 9-1

Figure 9-3

Battery

Charger

White +

Red +

Black

Black -

+

-

+

-

Battery

Charger

White +

Red +

Black

Black -

+

-

+

-

Figure 9-4

Note For oUtSIDe INStaLLS :

the battery charger

needs to be placed out of the weather.

16. Install chassis.

Bottom roller position. ensure

charging point is on

the bottom.

[Figure 9-2]

caUtIoN

Use caution when

handling battery.

caUtIoN

ensure charging fingers

are set as low as possible

to ensure there is no inter-

ference with rail support.

Slide on until drive hits the gear rack. Activate the joystick to drive onto rack, watching

the wheels to ensure they go on smoothly.

17. charging Station

•

Route red and black wires through hole provided in pipe by charging station

determine which end has the Ac power for the charger. connect the charger to the red

and black wires with the connectors provided.

[Figures 9-3 & 9-4]

clip off the green wire. (Not used)