Chapter 3

Control input/output

- -

18

3-5

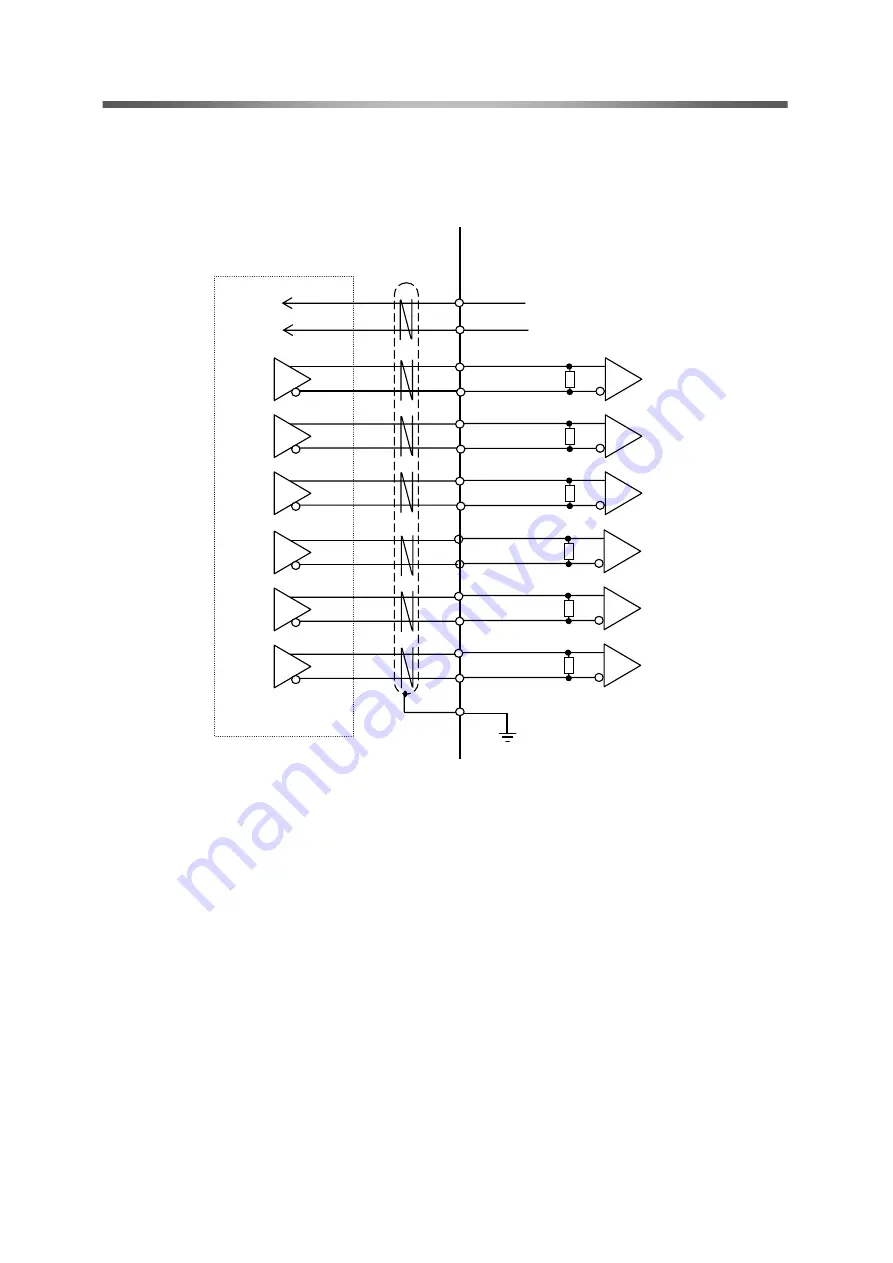

Encoder input (CN2)

◆

Function

Connect this with the AC servo actuator RSF/RKF Series encoder.

◆

Connection

(1) Connect the shielded wire securely to CN1-35 and 36.

A

−

B

−

Z

−

U

−

V

−

W

−

U

V

W

15

16

17

18

19

20

220

Ω

FG

Equivalent toAM26LS31

Actuator RSF/RKF Series

A

B

Z

+5V

0V

+

5V

0V

220

Ω

220

Ω

220

Ω

Driver HA-520

9

10

11

12

13

14

35,36

1

〜

4

5

〜

8

220

Ω

220

Ω

Equivalent to 26C32

Shielded