InstallatIon and operatIon Manual for WInd and sun screen sl400

09/12

|

7

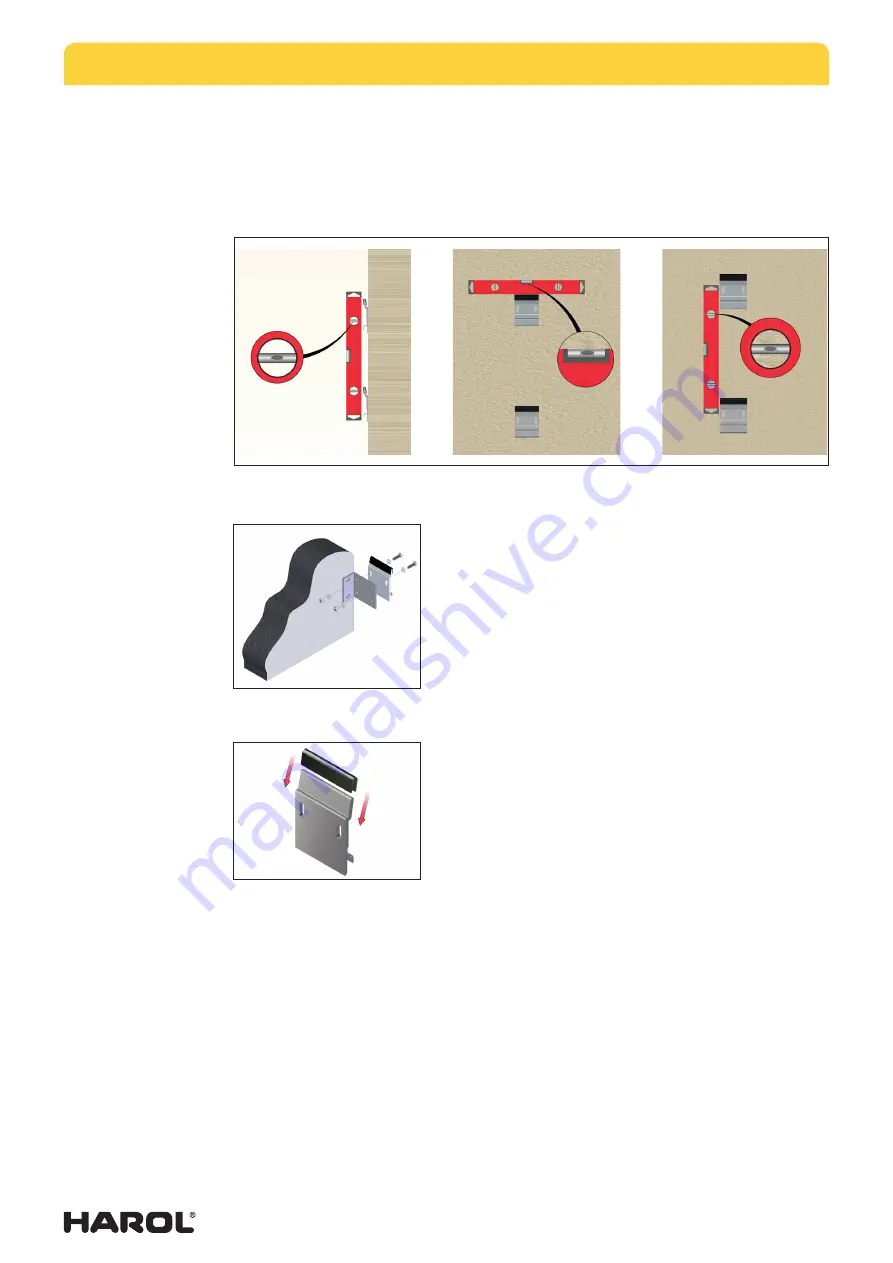

4.6. alignment of the wall brackets

the two wall brackets must be plumb and level. any irregularities in the mounting surface

must be compensated. take the time to make sure the screen is positioned perfectly vertically.

If the mounting surface is of poor quality, we recommend ordering additional brackets. also

check the distance between the brackets and then tighten all the screws. the mounted

screen is now ready for further adjustment and alignment of the supporting system.

4.7. optional mounting of the box (a2638)

Instead of mounting the wall brackets directly on to the wall,

it is also an option to use a wall console for each wall bracket.

Here too the choice of fastening materials depends largely

on the mounting surface and must be assessed by the fitter.

the mounting height of the wall consoles must match the

distance between the brackets on the box of the SL400.

once again, it is very important that the wall consoles are

aligned correctly.

4.8. Hooking up the box

a damping rubber is placed over each wall bracket. next, the

SL400 can be hoisted over the brackets and pressed down

so the screen is sufficiently protected and secure.

two people are required to attach heavier screens.

4.9. Installation of the supporting system

a supporting system should be installed at drop distance from the box in order to keep the

screen in the open position. this supporting system is for hooking up the pull rod.

there are various ways to do this:

•

floor assembly (a2642):

a support pin with ground support plate are anchored on

to the floor, optionally either a concrete anchor (option a2640) or a ground anchor

(a2641) can be used.

•

wall assembly (a2644):

a wall mounting block must first be mounted to the wall

using the appropriate fastening materials. next a short support is fastened to the

mounting block.

•

railing assembly (a2643):

a wall mounting block must first be mounted to the

railing using the appropriate fastening materials. next a support pin is fastened to

the mounting block.