Summary of Contents for Straw Blower 1800

Page 1: ...Straw Blower Straw Blower 1800 5 2016 OPERATOR S MANUAL...

Page 2: ...Straw Blower...

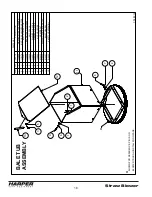

Page 8: ...Straw Blower 6...

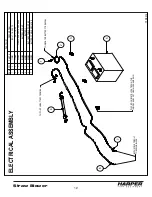

Page 19: ...Straw Blower R R...

Page 20: ...Straw Blower...

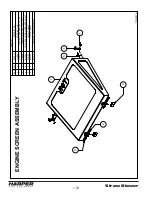

Page 35: ...Straw Blower...

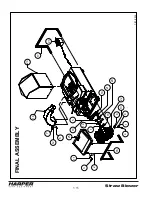

Page 41: ...Straw Blower NOTES...