MM-015371-001, Rev. C

28

5

PLANNING THE INSTALLATION

5.1 GENERAL INFORMATION

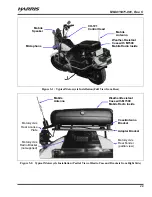

Figure 5-1 on page 29 illustrates a typical M5300/M7300 mobile radio motorcycle installation. Before

starting, plan the installation carefully so it will:

Be safe for the motorcycle operator;

Allow convenient access by the operator, as applicable (i.e., the control head);

Neat; and,

Allow easy service access.

CAUTION

A professional radio installer should perform the installation!

Mounting of the mobile radio components in ways other than those described in

this manual may adversely affect performance, violate FCC rules on RF exposure,

and even damage the unit(s), posing a potential safety hazard.

5.2 RECOMMENDED TOOLS

The following tools are recommended to complete the installation. Where specific vendor names and

model or part numbers are presented, equivalent substitutes may be used:

Non-Insulated Crimp Tool with Wire Cutter

similar to Thomas & Betts WT-111-M

Insulated Terminal Crimp Tool with Wire

Cutter similar to Klein 1005

Fuse Holder Crimp Tool similar to Thomas

& Betts – WT-112M or California Terminal

Products No. 1250 or Channelock No. 909

Ratcheting Hex-Crimp Tool for 50-Ohm

TNC and BNC RF Connectors and RG-58

Cable similar to Tyco Electronics 58433-2

(includes Crimper 354940-1 and Die Set

58436-1) or Cambridge 24-9960P

Metric and S.A.E. Socket Set with Sockets

to at least ½-Inch, a Nut Driver and an

Extension at least 3-Inches Long

Soft-Jaw Pliers similar to Tessco 450520 or

equivalent

Torx Screwdrivers, T10 and T20

Phillips-Head Screwdrivers, #1 and #2

Flat-Blade Screwdrivers, #1 and #2

4-Millimeter Hex Key Wrench

⅛

-Inch Hex Key Wrench (Allen Wrench)

Cordless Electric Drill(s) with Bits

Deburring Tool (for

⅜

-inch and smaller

holes)

Tie Wraps: 6-inches or larger

Flush-Cut and Large Wire Cutters

Various Fasteners (e.g., machine screws and

nuts, Tek screws, etc.)

A separate list of test equipment is included in Section 15.2 on page 70.