Lathe

Safety

I It. •• 1 IU�

. Every

effort has been ma.de.1n-the.design

and-production

of the.M400 lathe to comply with

statutory safety requirements and to provide a fundamentally safe machine tool.

In the further interests of safety, attention should be given to the following notes:-

A. Machine Capacity

The dimensions of a component which can be accommodated on the M400 lathe·are limited only

by the physical restrictions of the machine itself but responsibility for the following points with

respect to ·machining a component must inevitably rest with the user.

{ 1}

Ensuring that the operator has had suitable training and possesses the required degree of

skill and experience to undertake the work.

(2) · Providing suitable-work holding and/ or supporting equipment, i.e. chucks, steadies,

revolving centres, etc.

(3)

.Ensuring that suitable tooling is provided and correctly mounted.

(4)

Ensuring that suitable feeds and speeds a�e selected [if in doubt select the lowest).

(5)

Providing suitable workpiece guards and ensuring thatthese are consistently used.

8. Lathe Safety Rules

(1)

Read and understand operation notes before attempting to use the rn·achine.

(2) Keep lathe work areas clean.

(3) Keep area surrounding machine tidy.

(4) ENSURE YOU KNOW.HOWTO STOP THE MACHINE BEFORE STARTING IT.

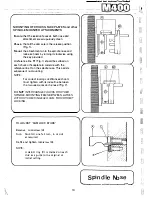

(5) · Do not interchange chucks or other spindle-mounting items between lathes without checking

for correct locking (see operational notes).

(6) Use only 'high speed' chl;lcks.

(7} Note maximum permissible speeds of faceplates (see operational notes).

(8) Remove chuck key immediately after use. ·

{9) Check load capacity of revolving centres.

(10) Ensure workpiece guards are in position before starting machine.

( 11)

Do not

use cracked or chipped tools.

( 12) Check - Spindle control lever is in stop position before starting motors.

Spindle speed selected.

Feed rate selected.

.

.

Direction of feed, and that

Feed & thread cutting levers are disengaged before starting the spindle.

(13) STOP MACHINE IMMEDIATELY ANYTHING UNEXPECTED HAPPENS.

(14)

Do not use coarse feed range on high spindle speeds (see operational notes).

(15)

Do not

change spindle speeds when spindle is rotating.

(16) Do not touch revolving chuck, spindle, or workpiece.

( 17) Do not remove work from the machine without re�reating the tool to a safe position.

( 18) Stop motors and switch off isolator when leaving machine unattended.

10

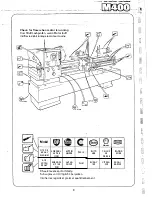

Summary of Contents for M400

Page 1: ...420mm 16 1 2 heavy duty centre lathe Operations Manual info harrisonlathe com 800 575 2843 ...

Page 6: ... t _ ___ 1n_s_t_a_lla_ t_io_n___ J 3 ...

Page 14: ... 2 I _ N I r 1 __ lilt n I I 1 II CJ t k J 29 1 Jit S fi IZ n I 28 i i i Ii ...

Page 19: ...I i f n u 17 Thread cutting ...

Page 25: ...i _1 L l fi l l b f_ _ _1 1 J 0 U C l 23 ____J Maintenance i I i ...

Page 33: ...n td j t L f _J r i J Llf J I 7 r l LJ __ P_a_rt_s_ _s_e_c_ti_o_n __J ...

Page 36: ... _ d i I O i I L l LJ 400 4 79 t M8x30 FV D001H2093 D272H1002 M16x75 FH r l M16 FN 35 V 401 1 ...

Page 46: ...t 1 l 4 79 403 050 403 051 A03 058 SP 996 M12 1 L D4o t 45 SP996M12 j 03 053 403 3 ...

Page 52: ...M8 Fl 1ETRIC J0 4 111 7 16 50 813 30 4 160 304 162 404 5 ...

Page 66: ...M20 FH A 02O WN 411 028 1 411 025 4 11 026 411 14 64 J ...

Page 67: ...r 1 r J M16x60 FJJ 411 013 65 411 012 411 010 411 011 411 16 ...

Page 68: ...__ 411 052 66 411 050 41i Q53 411 31 i I J 1 t 1 I ...

Page 74: ...411 200 411 202 M10 Fll 411 205 0401H0001 72 411 204 M10x35 FY 3 411 67 ...

Page 83: ... LJ l J t f 1 I i 1 i J r s 0 i _____ _II j 1 J J 9 8 9 0 5 i 1 1 l s s I r i ...