MODU-FIRE

®

Forced Draft Gas-Fired Boiler 2500-3000

14

The combustion air supply must be completely free of chemical fumes which may be corrosive when burned in

the boiler. Common chemicals which must be avoided are fluorocarbons and other halogenated compounds,

most commonly present as refrigerants or solvents, such as freon, trichlorethylene, perchlorethylene, chlorine,

etc. These chemicals, when burned, form acids which quickly attack the boiler and the boiler stack. The result is

improper combustion and premature boiler failure.

Under no circumstances shall the boiler room ever be under a negative pressure.

Particular care should be taken when exhaust fans, compressors, air-handling units or other equipment may

rob air from the boiler. Note that this equipment might be in rooms other than the boiler room.

3.5.2.1

Air Inlet Requirements – United States (NFPA 54/ANSI Z223.1 & NFPA/ANSI 211)

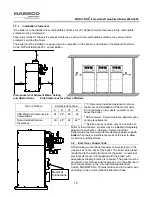

When air is supplied from inside the building, the total required volume shall be the sum of the required volume for

all the appliances located in the mechanical room. Adjacent rooms furnished with fixed openings communicating

directly with the mechanical room are considered part of the required volume. The minimum volume is 50 ft

3

per

1000 Btu/hr (4.8 m

3

/kW) of installed appliance input capacity.

Openings used to connect indoor spaces to obtain the required minimum volume shall be sized as follows:

When rooms are on the same floor, each opening shall have an area equal to 1 square inch for each 1000

Btu/hr (2200 mm

2

/ kW) of installed appliance input capacity, but not less than 100 square inches. One open-

ing should commence less than 12 inches above the floor and the other less than 12 inches below the ceiling.

The minimum dimension of air openings shall be 3 inches.

When rooms are on different floors, each opening shall have an area equal to 2 square inches for each 1000

Btu/hr (4400 mm

2

/ kW) of installed appliance input capacity.

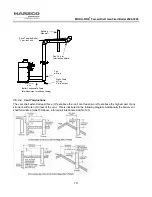

When combustion air is supplied from outside the building, the boiler room shall be provided with one or two

openings to ensure adequate combustion air and proper ventilation.

When using one permanent opening, the opening shall commence within 12 inches of the ceiling and shall com-

municate directly with the outdoors or through a vertical or horizontal duct that communicates to the outdoors.

Minimum free area of the opening is 1 square inch for each 3000 Btu/hr (700 mm

2

/ kW) of installed appliance

input capacity, and

Not less than the sum of the areas of all vent connectors in the room.

When using two permanent openings, one opening shall commence within 12 inches above the floor and the oth-

er within 12 inches below the ceiling, preferably on opposite walls. The openings shall communicate directly, or

by way of ducts, with free outdoor air. The minimum net free area of the openings shall be calculated in accord-

ance with the following:

When air is taken directly from outside the building, each opening (minimum of two, as outlined above), 1

square inch for each 4,000 Btu per hour (550 mm

2

/kW) of total boiler input is required.

When air is taken from the outdoors through a vertical duct into the mechanical room, 1 square inch per 4,000

Btu per hour (550 mm

2

/kW) of total boiler input is required.

When air is taken from the outdoors through a horizontal duct into the mechanical room, 1 square inch per

2,000 Btu per hour (1100 mm

2

/kW) of total boiler input is required.

Summary of Contents for 1004905923

Page 2: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 2 ...

Page 45: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 45 6 1 3 Wiring Schematic ...

Page 48: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 48 6 1 6 Rear Junction Box ...

Page 49: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 49 6 1 7 Customer Connections ...

Page 56: ...MODU FIRE Forced Draft Gas Fired Boiler 2500 3000 56 ...