MACH

®

Gas Fired Boiler

26

Some leak test solutions, including soap and water, may cause corrosion. These solutions should be rinsed-off with

water after testing.

3.7

B

OILER

W

ATER

P

IPING

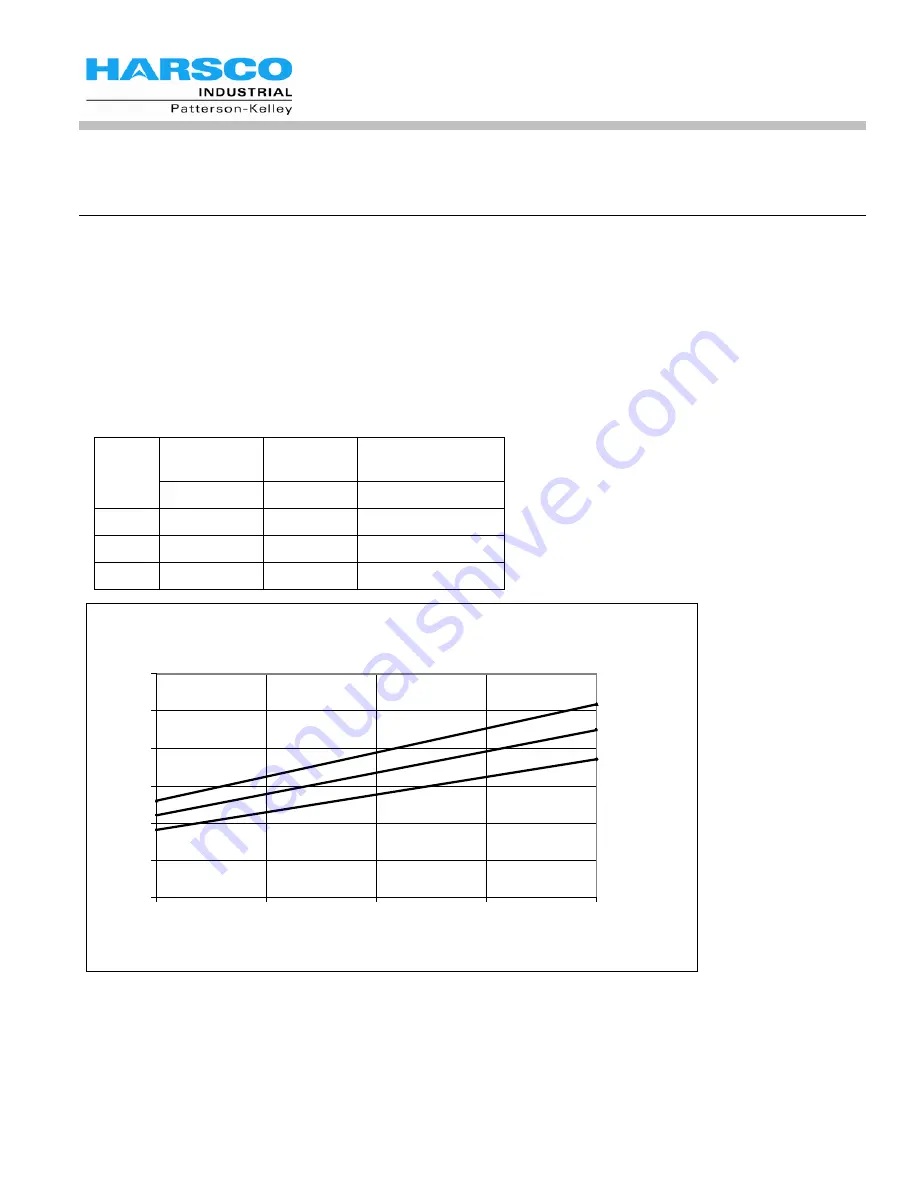

3.7.1 Piping Design

Water Flow in System/Pumping Requirements

See the charts below for proper water flow requirements. Incorrect flow may result in eventual damage or premature

failure of the equipment that may not be covered by warranty.

Proper flow rates may be achieved through a combination of primary and secondary flow loops. Multiple zones and

pumps may result in different flow rates at different times. Consideration must be given to all possible conditions and

their consequences.

Maximum Fire Rate

For minimum flow rates at other than maximum

firing rate, see MACH

®

Boiler Variable

Pumping Graph (below)

MACH Variable Pumping

0

10

20

30

40

50

60

20

40

60

80

100

Firing Rate (%)

F

lo

w

R

a

te

(G

P

M

)

C1050

C750

C900

Model

Max Flow

GPM

Min Flow

GPM

Pressure Drop (ft.)

at max flow

20°F ΔT

40°F ΔT

1050

105

52

12

900

90

45

12

750

75

37

12