MODU-FIRE® Forced Draft Gas-Fired Boiler

16

Table of Canadian Minimum Area of Combustion and Ventilation Air Openings

MFD

Required Combustion Air Opening

Ventilation Air Opening

Model #

Input (Btu/Hr)

in

2

mm

2

in

2

mm

2

N750

750,000

25

16,129

10

6,452

N1000

1,000,000

33

21,290

10

6,452

N1500

1,500,000

50

32,258

10

6,452

N2000

2,000,000

67

43,226

10

6,452

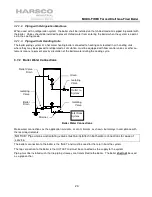

3.5.3 Flue Venting

This boiler is not certified for use with Type "B" vent nor with any type of plastic venting.

This boiler is a Category IV appliance (condensing – positive pressure) as it is defined in ANSI Z21.13/CSA 4.9,

latest edition. The vent material must be as described in section 3.5.1.2. The exhaust vent can be run horizontal-

ly or vertically.

Vent installations shall be in accordance with NFPA54/ANSI Z223.1, the

National Fuel Gas Code

, or CAN/CSA-

B149.1, the

Natural Gas and Propane Installation Code

, or applicable provisions of the local building codes.

Do not use a barometric damper with this boiler. This is a positive pres-

sure system. Flue gases may leak into the room.

This equipment MUST NOT be used with a heat actuated automatic vent

damper.

All boiler venting systems should be designed by a qualified venting profes-

sional experienced in venting system design. The information contained herein should be used as a

guide only and is not intended to be used in lieu of qualified technical expertise.

3.5.3.1 Vent Sizing

The vent must be sized in accordance with the ASHRAE Systems and Equipment handbook, Chapter 30 or ac-

cording to the vent manufacturer’s recommendations. When using manufactured venting systems, consult your

vent supplier for correct sizing and structural support requirements.

The vent must be sized according to the vent manufacturer’s recommendations.

Consult your vent

supplier for correct sizing and structural support requirements.

Design calculations for a single boiler/single stack installation should be based on a positive pressure at the flue

collar of 1.0” w.c. (not to exceed 2.0” w.c.) with a stack temperature of 325° F (gross) and a CO

2

level of 8.5%

(natural gas) or 9.9% (propane).

The vent should be designed to provide positive pressure at the flue collar at all firing rates.

Additional care must be used with sidewall venting as the exhaust velocity is high and the exhaust gas plume may

extend significantly beyond the termination.