MODU-FIRE® Forced Draft Gas-Fired Boiler

20

3.5.3.4.1 Vertical Venting

Harsco Industrial, Patterson-Kelley does not recommend the use of a vent cap. A screen

termination is not recommended due to the possibility of ice formation on the screen. Vent

terminations include open or reducing cone. Rain is actually beneficial to the vent

internals.

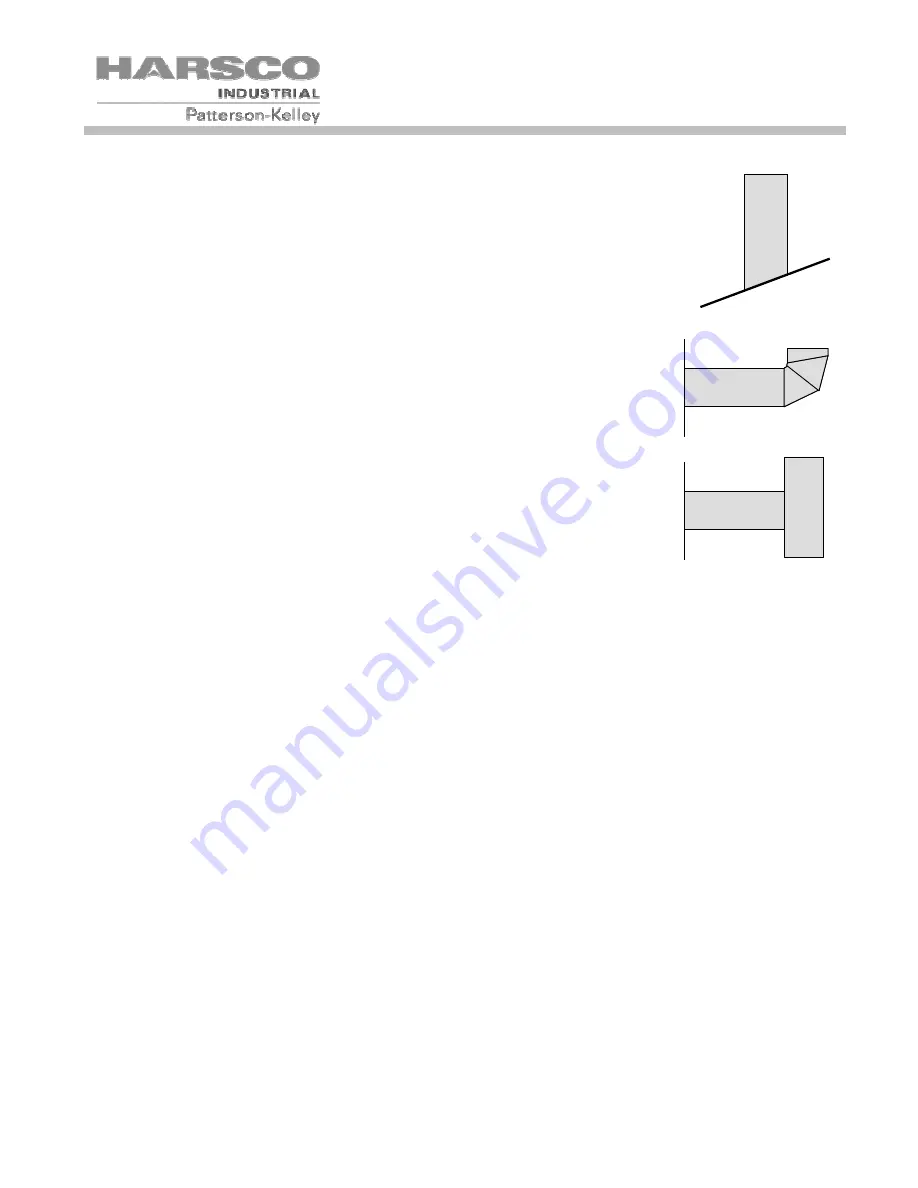

3.5.3.4.2 Sidewall Venting

Harsco Industrial, Patterson-Kelley requires a “T” or 90 degree elbow to be used on the

termination end of sidewall venting on these models. The venting connection for this “T” or

90 degree elbow should extend a minimum of 12” from the wall, in addition to other

venting requirements.

3.5.4 Venting for Multiple Boilers

The venting instructions in this manual apply to a single boi-

ler.

Venting systems for multiple boilers must be de-

signed by experienced and knowledgeable profes-

sionals.

The venting system must prevent backflow of ex-

haust gas through idle boilers.

3.5.5 Sealed Combustion/Direct Vent Systems

The MODU-FIRE

®

Forced Draft boilers are also certified for operation with a sealed combustion air and

pressurized venting system. Such a system employs a sealed combustion air intake duct leading from outdoors

to the boiler and a sealed exhaust vent leading from the boiler and terminating outdoors. Air flow through the

system is maintained by the combustion air fan.

3.5.5.1 Intake Duct Materials and Sizes

The air intake duct can be fabricated from PVC, CPVC, single wall galvanized steel, or other suitable materials.

The duct must be rigid enough to maintain the full required cross sectional area under all operating conditions.

Proper sealing of the intake ductwork is necessary to prevent infiltration of air from conditioned space. Joints in

PVC or CPVC must be cemented. For galvanized duct, wrap each joint and seam with adhesive aluminum tape

or other sealant. Connect the air supply duct to the inlet air collar on the boiler. This collar is 7-7/8” OD. Fasten

the duct to the collar with sheet metal screws and seal with aluminum tape or sealant. The installation of a

birdscreen on the intake termination is recommended. Ensure that the screen does not become blocked with

snow, ice, insects and other natural or man-made obstructions.

The combined pressure drop of the air supply duct and exhaust vent must not exceed 2.0” w.c. This

combined pressure drop can be distributed over the intake or exhaust as needed provided that the air inlet

pressure loss does not exceed -0.5” w.c.

Thru the Wall

Note:

Elbow and Tee

May be oriented

in any direction

Thru the Wall

Note:

Elbow and Tee

May be oriented

in any direction

Thru the roof

Thru the roof