MODU-FIRE® Forced Draft Gas-Fired Boiler

22

components are certified to handle a maximum inlet pressure of 14 inches W.C. (1/2 psig.). If the available gas

pressure exceeds 14 inches W.C., a suitable additional intermediate gas pressure regulator of the "lock up" type

must be provided to reduce the pressure to less than 14 inches W.C.

The minimum allowable gas pressure for proper operation of the unit is dependent on the vent resistance at high

fire. The following chart details the minimum gas pressure required based on the static pressure at the boiler flue

gas outlet.

For Natural Gas:

Stack pressure:

Min. gas pressure required:

Less than 1” W.C.

4.5” W.C.

More than 1” W.C.

7.0” W.C.

For Propane, a minimum of 7 inches W.C. inlet gas pressure is required.

All threaded connections must be made using a pipe compound that is

certified resistant to the action of liquefied petroleum gases. Do not use Teflon tape on gas line

threads.

NOTICE! Piping must be installed such that no piping stresses are transmitted to the boiler. The boi-

ler shall not be used as a pipe anchor.

The boiler and all gas piping connections should be pressure-tested and must be checked for leaks before being

placed into service. Test with compressed air or inert gas if possible. The boiler must be disconnected at the

boiler manual shutoff valve (located at the end of the supplied gas train) from the gas supply piping system during

any pressure testing of the system at pressures in excess of 1/2 psig (14 inch W.C.). Some leak test solutions,

including soap and water, may cause corrosion. These solutions should be rinsed off with water after testing.

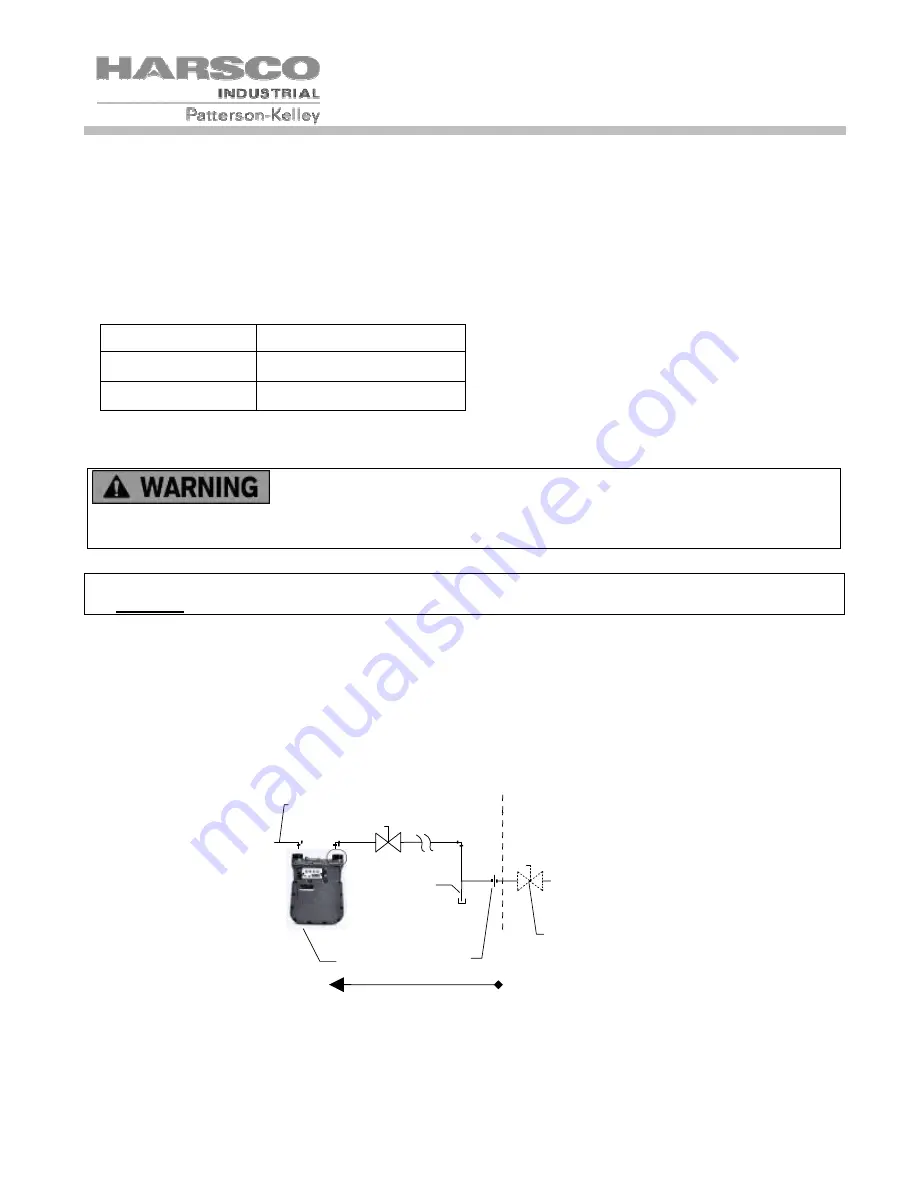

RECOMMENDED GAS PIPING INSTALLATION

Boiler Main Gas

Valve

Gas

Supply

Union

Drip Leg

Remote Gas

Shutoff

Meter

Field Gas Piping