MODU-FIRE® Forced Draft Gas-Fired Boiler

23

NOTICE! A sediment trap (drip leg) and a union connection should be installed downstream of the

primary manual shutoff valve on the boiler. Gas piping should be installed in accordance with Na-

tional Fuel Gas Code, ANSI Z223.1 and any other local codes which may apply. In Canada, please

refer to CSA-B.149.

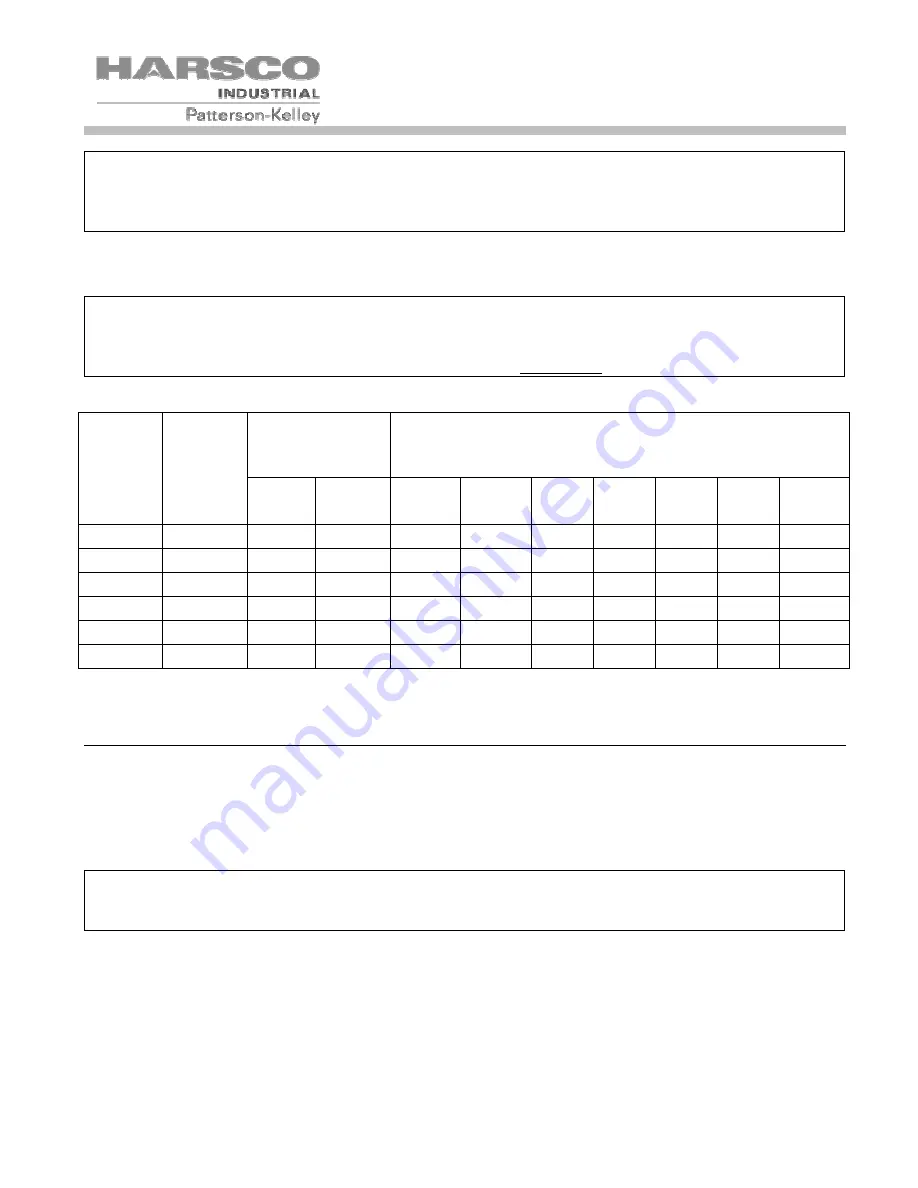

3.6.1 Pipe Capacity for Natural Gas

NOTICE! See Pipe Capacity for Natural Gas chart for required pipe size, based on overall length of

pipe from meter plus equivalent length of all fittings. Approximate sizing may be based on 1 cubic

foot of natural gas per 1,000 Btu per hour input, i.e., 500,000 Btu per hour requires about 500 cubic

feet per hour. (See "Typical Boiler Operating Conditions," Section 4.3, for more information.)

Nominal

Iron Pipe

Size

(Inches)

Internal

Diameter

(Inches)

Equivalent Pipe

Length

Maximum Capacity in Cubic Feet of Natural Gas per Hour

Pressure Drop of 0.5 inch Water Column/Equivalent Length of

Pipe (in feet)

90º Ell

(Feet)

Tee

(Feet)

20

40

60

80

100

150

200

1-1/4

1.380

3.45

6.9

950

1-1/2

1.610

4.02

8.04

1,460

990

810

2

2.067

5.17

10.3

2,750

1,900

1,520

1,300

1,150

950

800

2-1/2

2.469

6.16

12.3

4,350

3,000

2,400

2,050

1,850

1,500

1,280

3

3.068

7.67

15.3

7,700

5,300

4,300

3,700

3,250

2,650

2,280

4

4.026

10.1

20.2

15,800

10,900

8,800

7,500

6,700

5,500

4,600

3.7 B

OILER

W

ATER

P

IPING

3.7.1 Piping Design

3.7.1.1 Water Flow in System

Ideal operation of the MODU-FIRE

®

Forced-Draft boiler would consist of a 20º F temperature differential across

the heat exchanger at high fire. Insufficient flow may result in excessive short cycling of the boiler and eventual

damage or premature failure of the equipment.

NOTICE! The closing of the flow switch does not prove that flow is adequate. It only indicates that

some flow is present. Proper flow rates are 60-120 gpm for N750MFD and N1000MFD boilers,

90-150 gpm for N1500MFD and 120-180 gpm for N2000MFD boilers.

Minimum Return Water Temperature should be greater than 130º F to avoid problems of condensation on the

outside of the heat exchanger or in the flue passages.

Proper flow rates and return water temperature may be achieved through a combination of primary and secondary

flow loops. Multiple zones and pumps may result in different flow rates at different times. Consideration must be

given to all possible conditions and their consequences.