MODU-FIRE® Forced Draft Gas-Fired Boiler

28

temperature control (see Section 3.11 for instructions on setting this control). After completion of these tests, re-

adjust the operating thermostat to the desired operating temperature and set high-limit temperature, typically 20º

F above operating temperature.

3.10.4 Test of Low Gas Pressure Switch

Hi/Low Gas Pressure Switch

The boiler is furnished with a low gas pressure switch. The operation of this switch must be checked by slowly

closing the main gas cock while the burner is operating. The switch should shut down the main burner. The

control will display LOW GAS PRESSURE. This is a manual reset error and the boiler should not start until the

gas valve is opened, the low gas pressure switch is reset, and the control is reset.

3.10.5 Test of High Gas Pressure Switch

The boiler is furnished with a high gas pressure switch. The operation of this switch must be checked by closing

the downstream main gas cock, and starting the boiler. Once the trial for ignition period is reached, the main gas

valve will open, pressurizing the line. This will trip the high gas pressure switch. The switch should shut down the

main burner. The control will display HIGH GAS PRESSURE. This is a manual reset error and the boiler should

not start until the gas valve is opened, the low gas pressure switch is reset, and the control is reset.

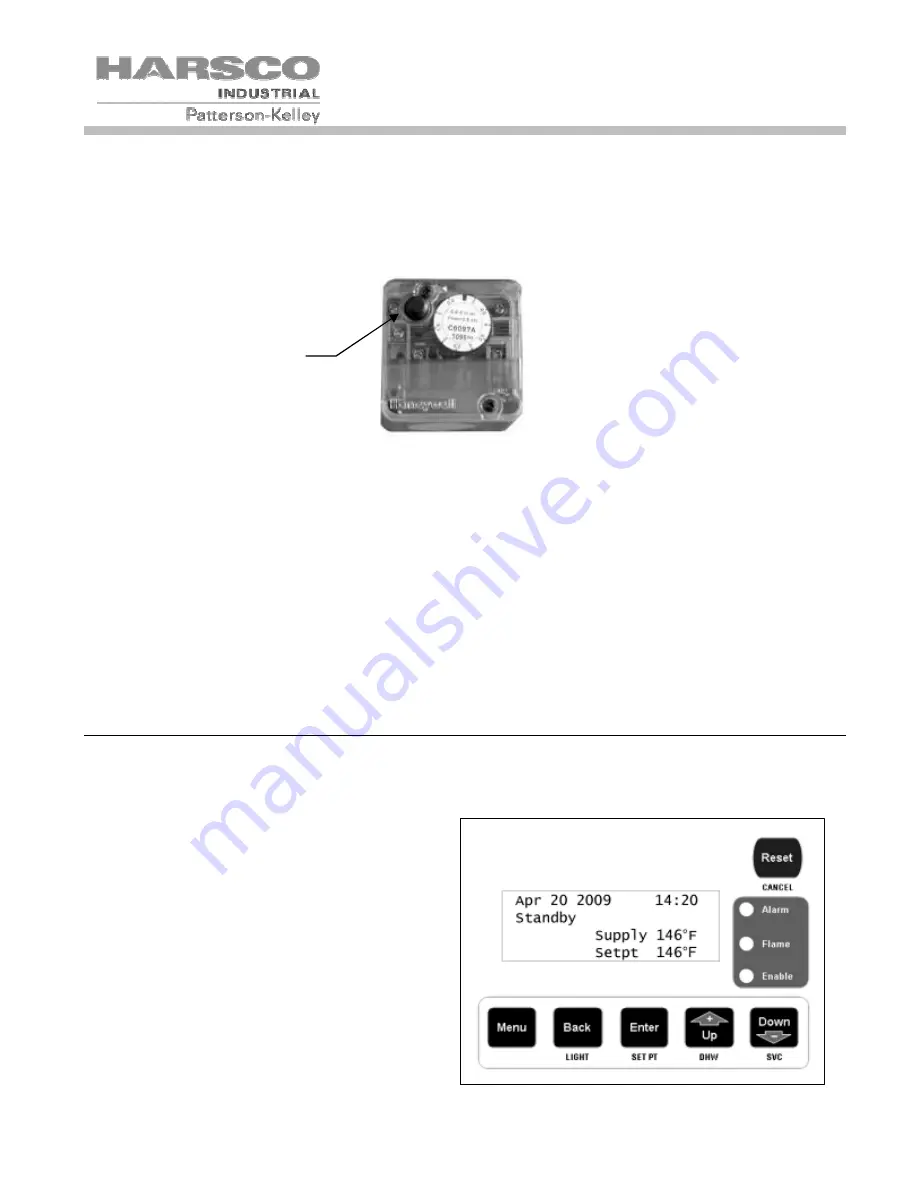

3.11 Boiler Operating Control

The MODU-FIRE® Forced Draft boiler is equipped with a combination combustion and temperature control. This

control monitors combustion and lighting of the boiler, as well as maintaining temperature of the supply water.

The temperature control portion modulates the boiler to maintain the desired outlet temperature based on the

selected operating configuration.

3.11.1 Initial Adjustments

The MODU-FIRE

®

Forced Draft 750-2000 boilers are

equipped with ENVI™ control; an intelligent control

system with advanced features such as text-based

display, communication capabilities, and boiler

sequencing. Errors are date and time stamped

providing built-in history of boiler status and

performance. This control constantly tracks the load

by recording burner high, low and mid run hours. One

control to do it all – temperature control, flame

safeguard, firing rate control, blocked flue protection,

outdoor air reset, freeze protection, built-in cascade

sequencing, MODBUS® communication and more.

Manual Reset