14

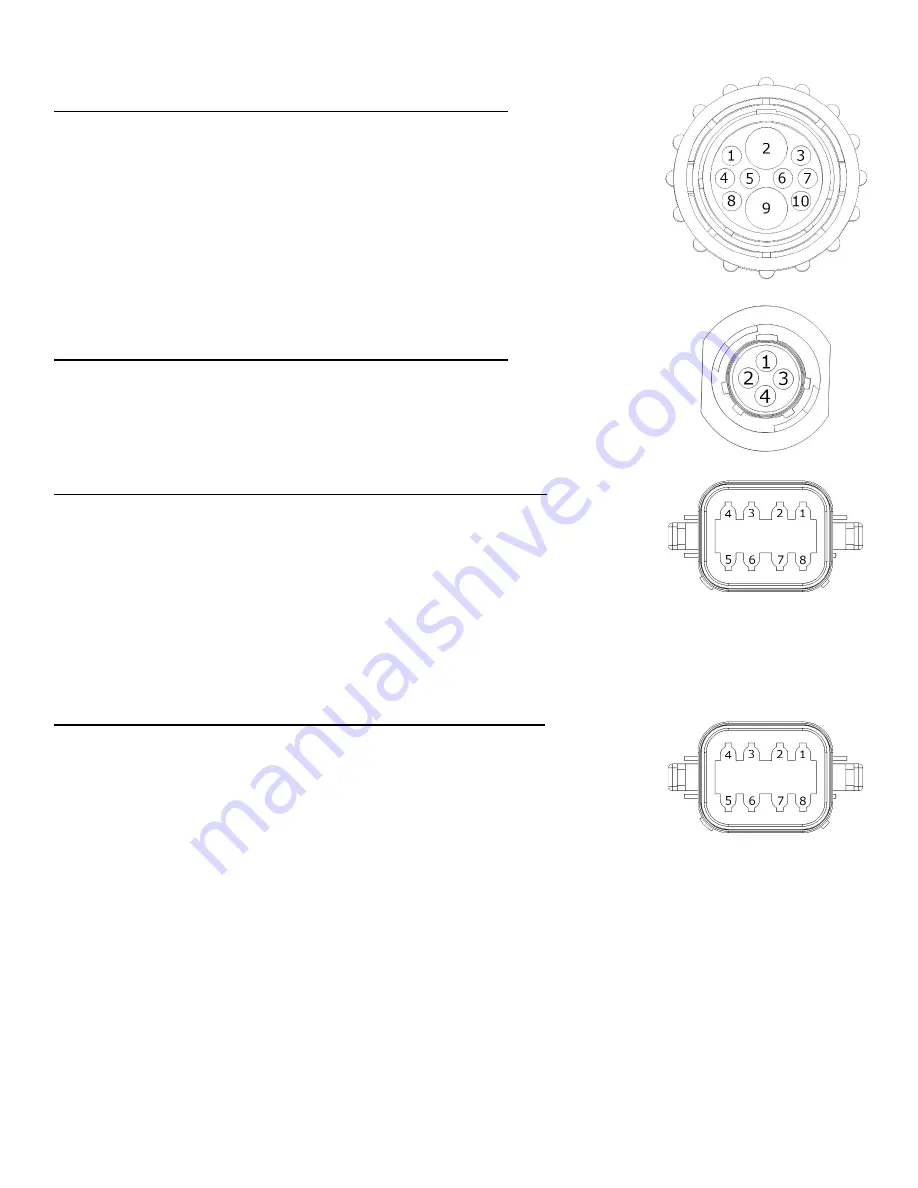

Pin Outs (continued)

Microwave Pre-Compression Chamber Harness 006-6650MW

Pin 1 Red

Power

Pin 2 N/A

Not Used

Pin 3 N/A

Not Used

Pin 4 Yellow

Can H In

Pin 5 Green

Can L In

Pin 6 Orange

Can H Out

Pin 7 Blue

Can L Out

Pin 8 Black

Ground

Pin 9 N/A

Not Used

Pin 10 N/A

Not Used

Microwave Pre-Compression Chamber Harness 006-6650MW

Pin 1 Red

Power

Pin 2 Black

Ground

Pin 3 N/A

Not Used

Pin 4 Brown

Signal

Microwave Pre-Compression Chamber Harness 006-6650MW (RX)

Pin 1 Black

Ground

Pin 2 Red

Power

Pin 3 Yellow

Can H

Pin 4 Green

Can L

Pin 5 Plugged

Pin 6 Plugged

Pin 7 Brown

Signal

Pin 8 Black

Ground

Microwave Pre-Compression Chamber Harness 006-6650MW (TX)

Pin 1 Black

Ground

Pin 2 Red

Power

Pin 3 Yellow

Can H

Pin 4 Green

Can L

Pin 5 Plugged

Pin 6 Plugged

Pin 7 Plugged

Pin 8 Plugged