7.

CAUTION:

The lathe bed is heavy. Have someone help lift it on the stand.

8.

Position the lathe bed so that the holes in the lathe bed are directly above the

holes in the stand.

9.

Secure the lathe bed to the stand using the eight M8 x 35mm Hex head screws

(A) Fig. 9 through the lathe bed and through the stand. Attach a washer, lockwasher,

and nut and tighten securely.

10. Before tightening all hardware, press down on stand until legs adjust to floor

surface. Securely tighten all hardware.

11. Slide the tool rest and tailstock back into the lathe bed.

12. Have someone help lift the headstock on the lathe bed and slide it into position.

HEADSTOCK SPUR CENTER

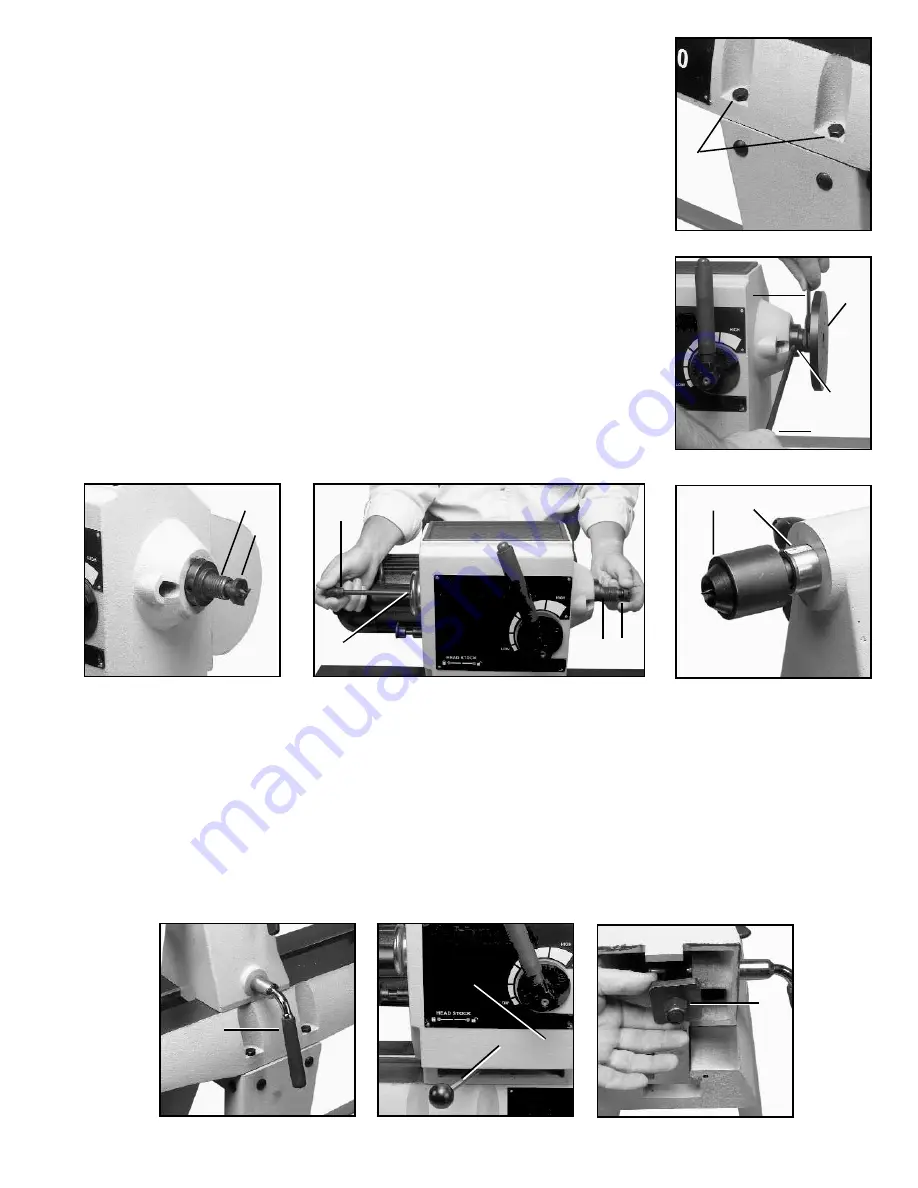

The 46-715 comes with a faceplate attached. Before inserting the spur center in the

spindle, this faceplate must be removed. Insert the knockout bar (A) Fig. 10 in the side

hole of the spindle (B) Fig. 10 to hold the spindle in place. Use the supplied wrench (C)

Fig. 10 to loosen the faceplate. Remove the faceplate (D) by turning it counterclock-

wise with your hand. The spur center (A) Fig.11 is equipped with a No. 2 Morse Taper

shank. Insert this shank into the headstock spindle (B).

NOTE:

Before inserting the spur

center (A), clean both the shank of the spur center and the inside of the headstock

spindle to remove any grease or debris. To remove the tapered shank spur center (A)

Fig. 11 from the headstock spindle (B) Fig. 11, use the knockout bar (C) Fig. 12 through

the hole (D) in the opposite end of the spindle to push the spur center out.

IMPORTANT: NEVER DRIVE THE WORKPIECE INTO THE SPUR CENTER WHEN

IT IS MOUNTED IN THE HEADSTOCK

.

See instructions on setting the spur center into the workpiece in the

“OPERATION“

section of this manual under “

CENTERING THE WORK

.”

Fig. 9

Fig. 10

Fig. 11

TAILSTOCK LIVE CENTER

Fig. 12

Fig. 13

The tailstock live center (A) Fig. 13, supplied with your lathe, is equipped with a No. 2 Morse Taper shank.

NOTE:

Before

inserting the live center, clean both the shank and the inside of the tailstock to remove any grease or debris. To remove the

live center (A) from the tailstock spindle (B), use the knockout bar through the hole in the opposite end of the spindle (in the

same manner as the headstock).

ADJUSTING CLAMPS ON THE HEADSTOCK AND TAILSTOCK

The headstock and tailstock can be moved along the lathe bed. A downward push on the tailstock handle (A) Fig. 14 locks

the mechanism, while an upward movement of the handle releases the securing action. The headstock (A) Fig. 15 is loosened

by moving the handle (B) to the right. The clamps are pre-set at the factory. However, should either need adjusting, use a

15/16" wrench to slightly loosen or tighten the nut (A) Fig. 16 shown here on the tailstock.

NOTE: Clamp headstock and

tailstock firmly before operating the lathe.

Fig. 14

Fig. 15

6

Fig. 16

A

B

A

B A

D

C

B

A

A

B

D

C

A

A

B

A