Air Driven Air Amplifiers, AAD-2 & AAD-2-C • OM-9J

6

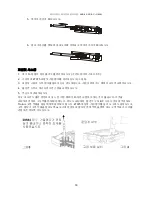

NOTE: Care must be taken in disassembly and assembly that the flow and pilot tube o-rings be on the

flow and pilot tubes prior to assembly. Alternately (cross-wise) torque tie rods to a maximum torque of 16-

18 foot pounds.

Check Valves

Remove and inspect parts (Ref. dwg. 27360). Replace 28119 seats if damaged.

Troubleshooting Guide

Symptom Cause Remedy

1. Will not run at low air drive

pressures

(10 - 15 psi)

1. Excess friction of spool o-

rings 568017.

1. Necessitates relubrication or

replacement of spool o-rings.

(See instruction for removing

spool in Figure 2, steps 1, 2,

3.)

2. Pump will not cycle, or slow

cycling.

1. Leakage of flow and/or pilot

tubes.

2. “Iced up” exhaust vent.

3. Indication that one or both

pilot valves are

malfunctioning.

4. Build-up of residue in muffler.

1. Replace o-rings on flow pilot

tubes.

2. Remove ice.

3. Remove pilot valves, inspect

and repair per instructions in

maintenance section.

4. Remove muffler,

disassemble and clean.

1. Small inlet air supply piping

magnifies any internal

leakage.

1. Increase air inlet piping and

replace o-rings in the

following order (test each

step):

a. No. 568015 o-ring

inside hex exhaust port

fitting.

b. Spool o-rings No.

568017.

c. Sleeve o-rings No.

568020. (See

instructions for

removing and replacing

o-rings.)

3. “False” or double cycling or

continuous exhaust bleeding.

2. Pilot stem valve damaged.

2. See steps 1, 2, 3 – Pilot

system maintenance.

4. Amplifier will not dead head

(stall)

1. Check valves contaminated

or damaged.

1. Remove, inspect, clean or

replace check valve parts as

necessary.

5. Excessive moisture or liquid

outside of muffler.

1. Air filter full of water.

1. Drain air filter.

6. Excessive bleeding out

diaphragm vent.

1. Piston rod seal leakage.

1. Replace diaphragm rod

seals. (Ref. dwg. 27379.)

7. Excessive “drag” noise.

1. Damaged piston seal 27363.

1. Replace. (Ref dwg. 27369.)