Hastings

Operations Manual

Page 16

TROUBLESHOOTING & FRQUENTLY ASKED QUESTIONS

The stove is very trouble free in operation when properly maintained and quality pellets are used.

When the stove fails to operate properly, troubleshooting by the operator of the stove is limited. Please

read the following guide for answers to frequently asked questions

1.

When first starting the stove remember the auger tube is empty, which will delay feeding fuel to

the burn pot. This will in some cases prevent the stove from starting.

Solution:

Prime the burn pot if the auger tube is empty.

2.

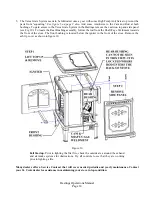

My stove isn’t burning and the number 2 Feed Light is blinking.

This diagnostic light

indicates the vacuum switch no longer senses negative pressure in the firebox area of the stove.

What caused the stove to go out?

a.

The door of the unit was left open longer than 60 seconds.

(See solution)

b.

The ash pan door was left open for longer than 60 seconds.

(See solution)

c.

The combustion fan is not running. (Defective fan or control board)

d.

The vacuum switch is defective.

e.

The vacuum hose is disconnected

a.

The vent system is plugged with fly ash.

Solution:

If the fire is out, re-light the stove. If the fire is still burning make sure all doors

are securely latched

and

hold down the On/Off

button (approximately 5 seconds)

until stove starts up again. This will restart the stove in the start-up program.

Occasionally use the auger button to manually feed fuel until the auto-feed takes

over

(Auto feed will start 5 minutes after the stove has been restarted).

3.

My stove isn’t burning and the number 3 Feed Light is blinking.

This diagnostic light

indicates that the Proof of Fire Switch no longer senses a fire in the stove. First check to see if

there are pellets in the hopper. If there are pellets in the hopper, why did the stove go out?

a.

Unburned fuel in the Burn Pot means the fire went out before the Auger

quit feeding.

Solution:

There is too much combustion air; adjust the air damper or the Draft Trim on

Level 1.

Pellets would still feed until the P.O.F. switch eventually shuts the stove

down (See

Damper Adjustment

in the Operations Manual and point 8 on page 17).

b.

If the Burn Pot is empty means the Auger quit feeding fuel while there

was still a fire in the burnpot. Check to see if there is fuel in the hopper. If

the hopper is empty, fill the hopper and re-light the stove.

c.

If there is fuel in the hopper, check to see if there is an obstruction in the

auger system or if the auger set screw is loose.

Solution:

Remove obstruction and re-light the stove or tighten the setscrew on the

auger shaft.