Hastings

Operations Manual

Page 8

THERMOSTAT

WIRE

TERMINAL

DAMPER

Combustion Air Damper

Figure 3

Damper Adjustment

When burning pellets make sure to check for

the formation of creosote in the unit and

venting system. Constantly running the stove

on a low setting with too much combustion air

may cause creosote to form. Burn pot

temperatures can be “too cool” when burning

on low with too much draft.

Adjusting the Damper may take a little time and

patience, but only needs to be done once. After

the damper has been adjusted to the venting

system in your home, the control board will do

the rest.

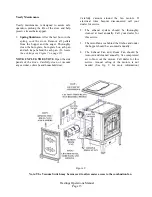

The purpose of this damper is to adjust

combustion airflow to match the characteristic of

each specific air inlet and chimney configuration.

There is a setscrew in the damper

(shown in

Figure 4)

and the damper has been preset at the

factory. This setting will most likely work for

90% of the most common installations. Long

horizontal runs might need the damper opened.

Tall vertical runs might need the damper to be

closed a little, etc. To adjust the damper, use the

setscrew to make the adjustments. To make an

adjustment turn the screw ½ turn clockwise to

open the damper or ½ turn counter clockwise to

close the damper. Remember to use the damper

handle to bring the damper up to the screw. The

damper will not close by itself. After making an

adjustment wait at least 15 minutes to see how

the burn pot reacts to the change.

Adjusting the

damper during the break in period is very

important (See “Preventing Chimney Fires” on

page 2)

. Break-in requires the burning of 15 bags of

pellets or continuous burn for two weeks. If during

the initial break-in period you experience difficulty

keeping the stove burning or there appears to be an

excessive amount of burning pellets being evacuated

from the burn grate, it may be necessary to close the

damper some more. Once the damper is fine tuned

for settings 1, 2, 3 and 4 the stove will run fine

without having to make a change to the damper

setting unless the stove is run on 5 for extended

periods of time. It is normal for ash and some sparks

to be continually evacuated from the burn grate. This

is how the grate continuously cleans itself. The

equivalent of a teacup of unburned pellets a day in

the ash pan is considered normal.

Figure 4

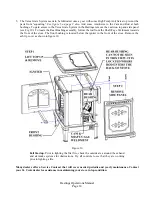

Flame Pattern Characteristics

Correct Flame Pattern -

Bright yellowish-white

flame with a brisk movement, having sharp pointed

end tips extending up towards the Heat Exchange

Tubes while forming a fan-like shape. Small

amounts of ash and some live sparks being blown

out from the Burn Pot area is considered normal

operation.

Incorrect Flame Pattern -

Dark orangish-brown

flame with a lazy movement, having black smoky

end tips curling up and over the Heat Exchange

Tubes while forming a fireball-like shape. Some Ash

or Live Sparks not being blown out from the Burn

Pot area is considered abnormal operation.

Extremely black soot forming on the ceramic glass

surface is a sign of very poor combustion (not

enough combustion air) and should not be

overlooked. At the other end of the spectrum; an