MAINTENANCE

8

Form No. MDWM-0608

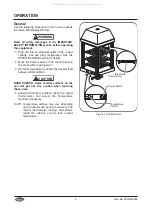

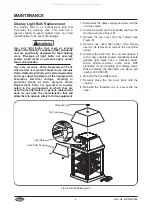

Figure 9. Bulb Replacement

Threaded Cap

Top Cover

Hood Filler Panel

Light Bulb

Display Light Bulb Replacement

The display light is an incandescent bulb that

illuminates the warming area. This bulb has a

special coating to guard against injury and food

contamination in the event of breakage.

Use only light bulbs that meet or exceed

(National Sanitation Foundation (NSF) standards

and are specifically designed for food holding

areas. Breakage of light bulbs not specially

coated could result in personal injury and/or

food contamination.

Use only Genuine Hatco Replacement Parts

when service is required. Failure to use Genuine

Hatco Replacement Parts will void all warranties

and may subject operators of the equipment to

hazardous electrical voltage, resulting in

electrical shock or burn. Genuine Hatco

Replacement Parts are specified to operate

safely in the environments in which they are

used. Some aftermarket or generic replacement

parts do not have the characteristics that will

allow them to operate safely in Hatco equipment.

1. Disconnect the power supply and wait until the

unit has cooled.

2. Unscrew and remove the threaded cap from the

the top cover (see Figure 9).

3. Remove the top cover from the cabinet (see

Figure 9).

4. Remove one hood filler panel. (Two screws

need to be removed to remove the hood filler

panel.)

5. Unscrew the bulb from the unit and replace it

with a new specially coated incandescent bulb

(display light bulbs have a threaded base).

Hatco shatter-resistant bulbs meet NSF

standards for food holding and display areas.

When replacing the light bulb, use Hatco part

number 02.30.043.00.

6. Reinstall the hood filler panel.

7. Securely place the top cover back onto the

cabinet.

8. Reinstall the threaded cap to secure the top

cover.

WARNING

All manuals and user guides at all-guides.com