INSTALLATION

Form No. MDWM-0608

5

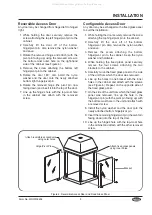

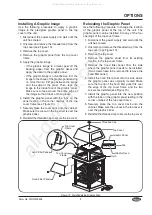

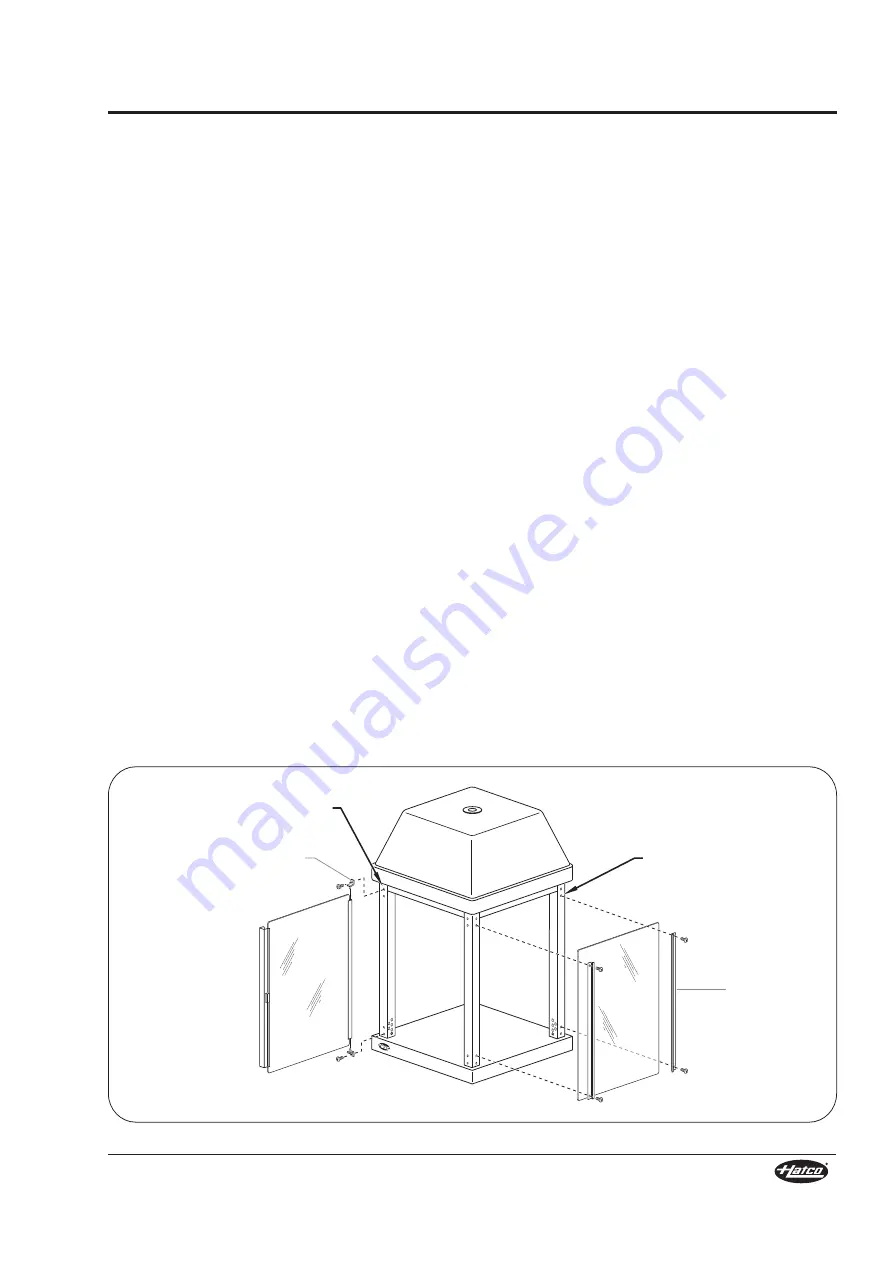

Reversible Access Door

Any door may be changed from hinged left to hinged

right.

1. While holding the door securely, remove the

screw attaching the top left hinge/pivot pin to the

cabinet.

2. Carefully lift the door off of the bottom

hinge/pivot pin. Also remove the nylon washer

and save.

3. Rotate the removed hinge and attach (with the

pivot pin facing up) using the removed screw to

the bottom-most outer hole on the right-hand

side of the cabinet (see Figure 6).

4. Remove the screw attaching the bottom left

hinge/pivot pin to the cabinet.

5. Rotate the door 180° and install the nylon

washer and the door onto the newly attached

bottom right hinge/pivot pin.

6. Rotate the removed hinge (the pivot pin now

facing down) and insert it into the top of the door.

7. Line up the hinge’s hole with the top-most hole

in the cabinet and attach with the removed

screw.

Configurable Access Door

Any door may be exchanged with a fixed glass panel

to suit the installation.

1. While holding the door securely, remove the screw

attaching the top hinge/pivot pin to the cabinet.

2. Carefully lift the door off of the bottom

hinge/pivot pin. Also remove the nylon washer

and save.

3. Remove the screw attaching the bottom

hinge/pivot pin to the cabinet. Keep the nylon

washer and hardware.

4. While holding the fixed glass panel securely,

remove the four screws attaching the two

brackets to the cabinet.

5. Carefully move the fixed glass panel to the side

of the unit from which the door was removed.

6. Line up the holes in one bracket with the inner

holes in the cabinet and attach with the screws

(see Figure 6). Repeat on the opposite side of

the fixed glass panel.

7. On the side of the unit from which the fixed glass

panel was removed, line up the hole in the

hinge/pivot pin (with the pivot pin facing up) with

the bottom-most hole in the unit and attach with

a removed screw.

8. Install the nylon washer and the door onto the

newly attached bottom hinge/pivot pin.

9. Insert the remaining hinge/pivot pin (the pivot pin

facing down) into the top of the door.

10. Line up the hinge’s hole with the top-most hole

in the cabinet and attach with the other removed

screw.

Figure 6. Reversible Access Door and Fixed Glass Panel

Attach fixed glass panels

using inner holes.

Attach reversible accessdoors

using outer holes.

Bracket

Hinge/Pivot Pin

All manuals and user guides at all-guides.com