OPTIONS AND ACCESSORIES

Form No. MDWM-0311

12

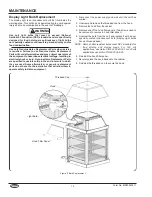

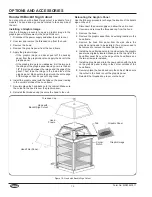

Graphic Panel

Graphic Image

Tab

Threaded Cap

Hood with

Backlit Sign Cutout

Hood

Frame

Hood Filler Panel

Corner

Notch

Figure 10. Hood with Backlit Sign Cutout

Hood with Backlit Sign Cutout

an optional hood with a backlit sign cutout is available for all

models. The hood and sign can be rotated to face any side of

the unit.

Installing a Graphic Image

Use the following procedure to apply a graphic image to the

graphic panel for placement in the hood of the unit.

1. Disconnect the power supply and allow the unit to cool.

2. Unscrew and remove the threaded cap from the hood.

3. Remove the hood.

4. Remove the graphic panel from the hood frame.

5. apply the graphic image:

• If the graphic image is a decal, peel off the backing

paper from the graphic decal and apply the decal to the

graphic panel.

• If the graphic image is non-adhesive, trim the image to

the shape of the graphic panel leaving no more than an

1/8″ (3 mm) gap between the image and the edge of the

panel. Then, tape the image to the inside face of the

graphic panel. Make sure to tape around the entire edge

of the image so that it does not hang loose.

6. Install the graphic panel with the tabs on the panel resting

in the corner notches of the hood frame.

7. Securely place the hood back onto the cabinet. Make sure

the cutout in the hood is over the graphic panel.

8. Reinstall the threaded cap to secure the hood to the unit.

Relocating the Graphic Panel

Use the following procedure to change the location of the backlit

sign on the unit.

1. Disconnect the power supply and allow the unit to cool.

2. Unscrew and remove the threaded cap from the hood.

3. Remove the hood.

4. Remove the graphic panel from its existing location in the

hood frame.

5. Remove the hood filler panel from the side where the

graphic panel needs to be installed. (Two screws need to

be removed to remove the hood filler panel.)

6. Install the hood filler panel onto the side where the graphic

panel was originally located. Make sure the top lip of the

hood filler panel fits over the edge of the hood frame and

the two screws are installed.

7. Install the graphic panel into the new position with the tabs

on the graphic panel resting in the corner notches of the

hood frame.

8. Securely place the hood back onto the cabinet. Make sure

the cutout in the hood is over the graphic panel.

9. Reinstall the threaded cap to secure the hood.

Summary of Contents for MDX-1X

Page 14: ...NOTES Form No MDWM 0311 14 ...

Page 15: ...NOTES Form No MDWM 0311 15 ...