- 7 -

7

、

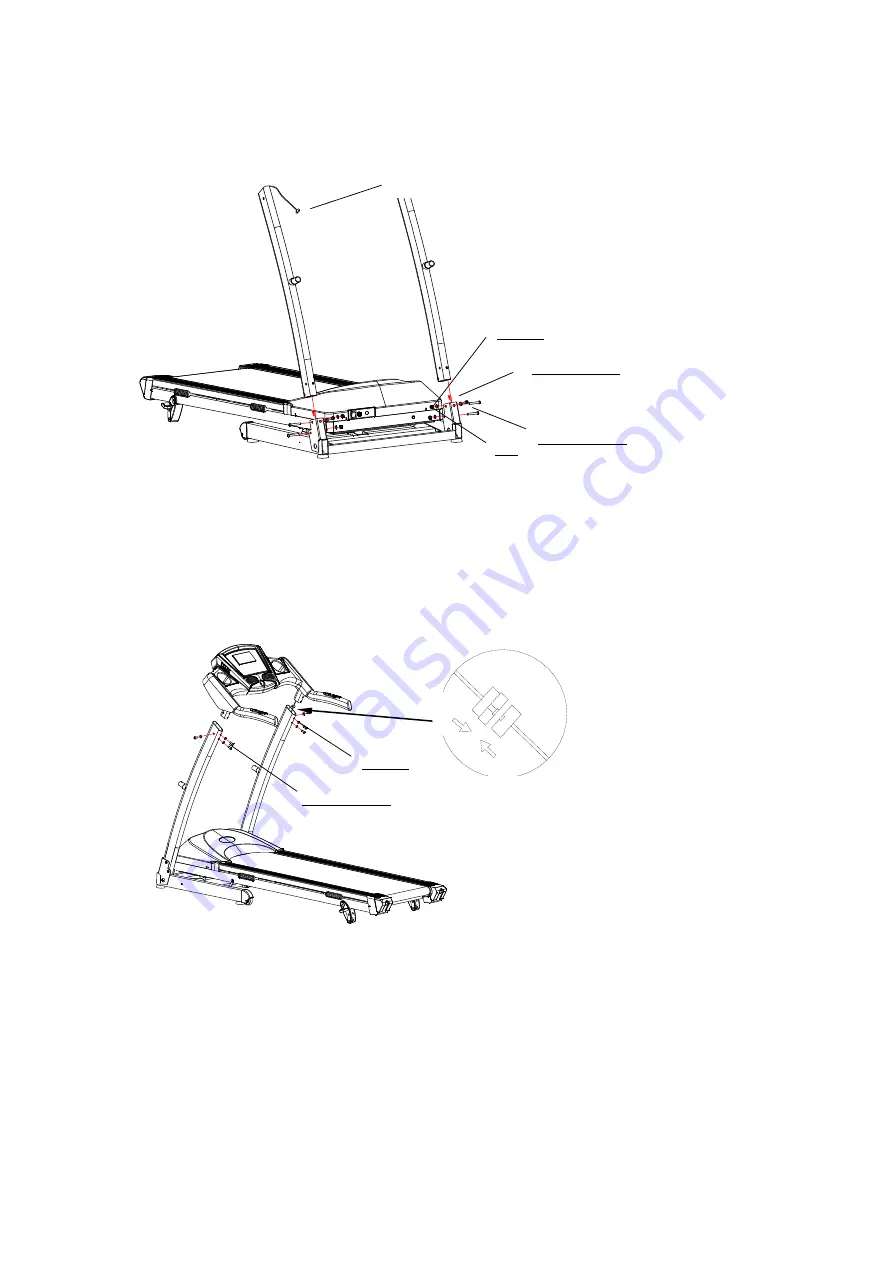

Installation

Step 1:

Install meter pillars

a)

Let the communication line pass through the right meter pillar.

b)

Put meter pillars on the base frame. First, use 2 Screw M8*15 and 2 washers;

second, use 4 Screw M8*50, 4 washers and 4 nuts to fasten meter pillars. (Don’t

tighten screws at first )

Step 2:

Install the meter

a)

Make sure that communication lines are connected correctly

b)

Put the meter on the meter pillars. Use 6 Screw M8*15 and 6 washers to fasten

the meter. (Don’t tighten screws at first)

c)

Turn power on and start the machine. If all functions work well, tighten all

screws in

Step 1

and

2

.

Screw M8x15

Washer

Screw M8x15

Washer

Communication line

Nut

Screw M8x50