Page 24

For technical questions, please call 1-888-866-5797.

Item 58702

Sa

FE

ty

Op

E

ra

ti

O

n

M

aint

E

nan

CE

a

SSEMBL

y

Maintenance

procedures not specifically explained in this manual must

be performed only by a qualified technician.

tO prEVEnt SEriOUS inJUry FrOM tOOL FaiLUrE:

Do not use damaged equipment. if abnormal noise or vibration occurs,

have the problem corrected before further use.

note:

Tow vehicles often have more frequent maintenance requirements, including changes of

engine and transmission oils and filters, lubrication of components, and cooling system checks.

Check your owner’s manual for information on scheduled maintenance of your tow vehicle.

BEFOrE EaCH USE: inspect the trailer and tow vehicle according to the instructions on page 16.

tires

1. Periodic inspection and maintenance of tires

and wheels are essential to towing safety,

including spare tires. Proper tire pressure affects

vehicle handling and the safety of your tires.

You can find the correct tire pressure for your

tow vehicle on the tire information placard.

2. Underinflation reduces the load-carrying capacity

of your tow vehicle or trailer, may cause sway and

control problems, and may result in overheating,

causing blowouts or other tire failure.

3. Overinflation causes premature tire wear

and affects the handling characteristics

of the tow vehicle or trailer.

Lubricate Wheel Bearings

1.

EVEry 2,000 tO 3,000 MiLES OF USE,

lubricate zerk fittings on back of Hub Assemblies

with a heavy-weight bearing grease.

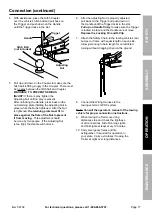

WarninG! Whenever a hub is disassembled

(if a hub on a new unit requires assembly

or a hub is disassembled for maintenance),

the following procedure MUSt be obeyed.

Failure to read and obey all of the following

instructions completely will void the warranty

and can result in damage to the trailer,

property damage, or serious injury.

2.

EVEry 20,000 MiLES OF USE,

clean and repack bearings:

a. Using a suitable solvent, thoroughly clean

bearings and the rest of the parts in Hub

Assembly of all grease, dirt, metal shavings,

or any other foreign object.

parts must be

cleaned even if they are new or

appear

clean.

b. Allow all pieces to dry completely.

c. Make sure that your hands are thoroughly

clean and bearing packer (not included)

is also thoroughly clean.

d. Place fresh, clean bearing grease in the packer.

e. With the grease-filled bearing packer in one

hand and bearing in the other, press bearing

into grease, forcing grease inside slots in

bearing. Continue doing this until every slot

in bearing is completely full of grease.

f. Reassemble Hub Assemblies.

g. Thread Castle Nut onto Axle until tire

starts spinning with slight resistance,

then back off slightly and line up gaps

in Castle Nut with holes in Axle.

h. Insert a new Cotter Pin through

Castle Nut and Axle. Bend pins in

opposite directions to secure tire.

i. Replace Dust Caps, tapping with

rubber mallet to seat them.