HAULOTTE GROUP

5 CYLINDER REPLACEMENT

70

TELESCOPING

BOOM

BASE END

CYLINDER

RETAINER

PIN

CYLINDER

SLAVE

ROD END

UPPER BOOM

JIB BOOM

CYLINDER

PIN

PIVOT

PIN

MASTER / SLAVE CYLINDER REPLACEMENT (CONTINUED)

Master Cylinder (Continued)

Place absorbent cloths below the cylinder ports and detach hydraulic hoses from the cylinder.

Elevate hoses to prevent leakage. Plug or cap exposed hose fittings and cylinder ports.

Unbolt and remove the pin retainer at the base end of the cylinder.

Remove the pivot pin using a hammer and a brass or hardwood drift.

Replace or reinstall the cylinder by following the above instructions in the reverse order of

removal.

Actuate the hydraulic system and check for leakage. Tighten hydraulic fittings as needed.

Bleed trapped air from the hydraulic system by raising and lowering the telescoping boom with the

reservoir fill port cap on, but not tightened. Allow several cycles of operation for trapped air to

escape. Repeat as necessary

.

Slave Cylinder

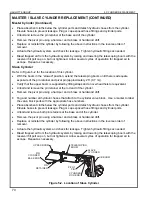

Refer to Figure 5–2 for the location of this cylinder.

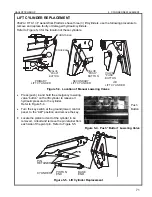

With the boom in the “stowed” position, extend the telescoping boom until there is adequate

exposure of the pin retainer and pivot pin (approximately 2 ft. (0.7 m)).

Verify that the upper boom is supported by lifting straps and an overhead hoist or equivalent.

Unbolt and remove the pin retainer at the rod end of the cylinder.

Remove the pivot pin using a hammer and a brass or hardwood drift.

Tag and number all hydraulic hoses that attach to the cylinder valve block. Use a marker to label

the valve block ports with the appropriate hose numbers.

Place absorbent cloths below the cylinder ports and detach hydraulic hoses from the cylinder.

Elevate hoses to prevent leakage. Plug or cap exposed hose fittings and cylinder ports.

Unbolt and remove both pin retainers at the base end of the cylinder.

Remove the pivot pin using a hammer and a brass or hardwood drift.

Replace or reinstall the cylinder by following the above instructions in the reverse order of

removal.

Actuate the hydraulic system and check for leakage. Tighten hydraulic fittings as needed.

Bleed trapped air from the hydraulic system by raising and lowering the telescoping boom with the

reservoir fill port cap on, but not tightened. Allow several cycles of operation for trapped air to

escape. Repeat as necessary.

Figure 5-2. Location of Slave Cylinder

Summary of Contents for 3522A

Page 1: ...OPERATOR S MAINTENANCE MANUAL B33 01 0093 Rev 4 May 2013...

Page 76: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 76 DECAL KIT ANSI...

Page 78: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 78 IDENTIFICATION PLATES OPTIONAL EQUIPMENT ANSI...

Page 84: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 84 DECAL KIT CE...

Page 86: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 86 IDENTIFICATION PLATES OPTIONAL EQUIPMENT CE...

Page 88: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 88 DECAL KIT AU...

Page 90: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 90 IDENTIFICATION PLATES OPTIONAL EQUIPMENT AU...

Page 92: ...HAULOTTE GROUP 6 DECAL REPLACEMENT 92...

Page 106: ...HAULOTTE GROUP 8 MATERIAL SAFETY 106 MATERIAL SAFETY DATA SHEET POWERFLOW AW HVI HYDRAULIC OIL...