106

24203 3237 0

E 06 10

EN

F

- Special procedure

Engine-powered articulated lifts, 12 - 26 m

For : HA260PX (HA80JRT)

3.2 - TOWING

The machine can be towed.

3.3 - RECONNECTING THE UNIT

After repairing the machine, reconnect the wheel gears.

For HA120PX (N/A)

• Machine without stabilizers

1.

Screw the central nut up again to engage the jaw clutch.

2.

Engage the driving command in micro-speed in case of resistance(By turning the wheels).

3.

Screw the central nut up completely when the jaw clutch is indexed.

For : HA16X - HA16SPX (HA46SJRT) - HA18SPX (HA51SJRT) - HA16PX (HA46JRT) -

HA18PX (HA51JRT) - HA20PX (HA61JRT)

Perform in reverse order to the gear disengaging procedure.

For HA260PX (HA80JRT)

Put the central plug back on each wheel.

N.B.-:-D

URING

REASSEMBLY

,

PLACE

THE

CENTRAL

PLUG

IN

THE

CORRECT

POSITION

ON

EACH

WHEEL

AND

TOP

UP

THE

OIL

LEVEL

IN

THE

GEARS

.

The gears are released.

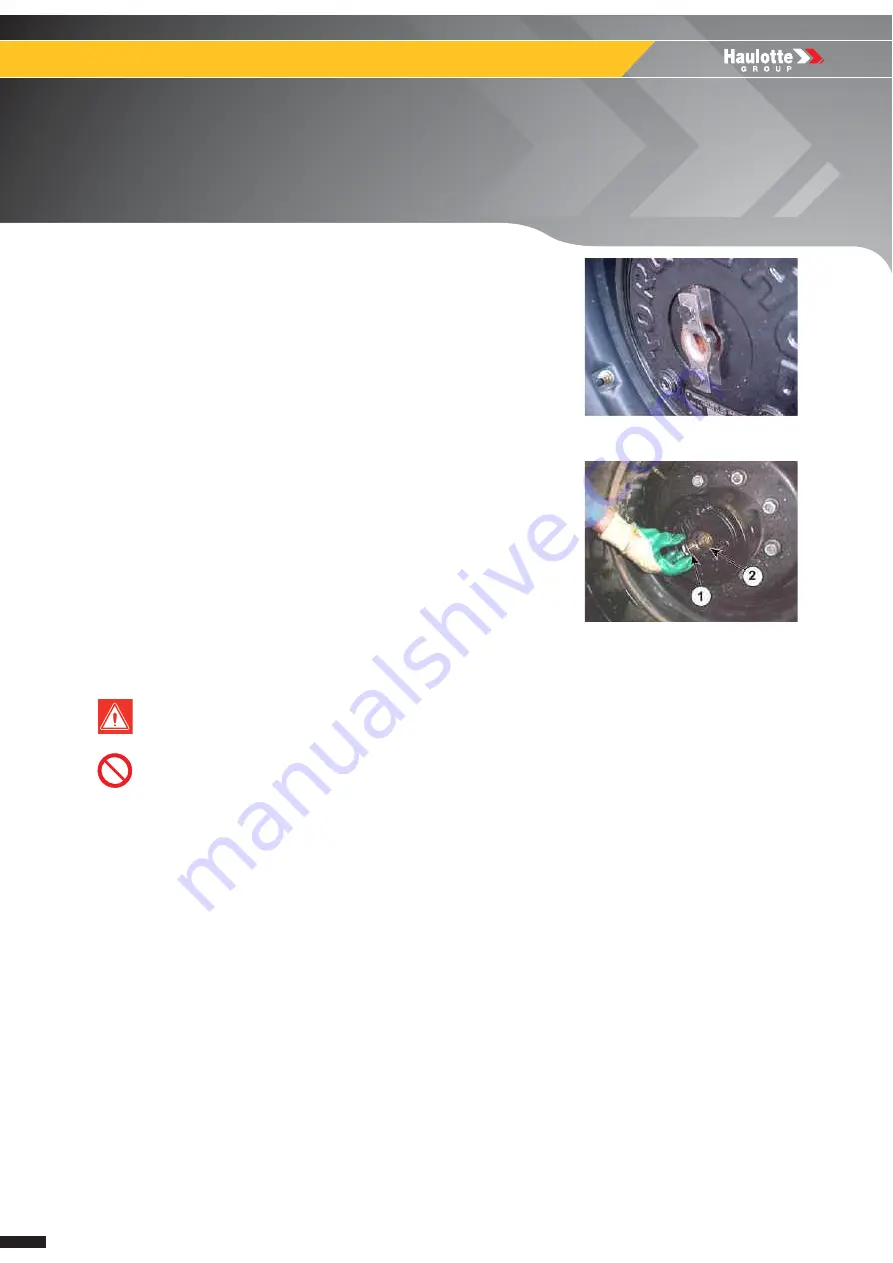

1.

Loosen plug ( 1 ) (Central nut).

2.

Remove the spline pin ( 2 ) using a 6 x 50 screw.

3.

Retighten plug ( 1 ).

In the towing configuration, the machine is no longer slowed down. Use a drawbar to avoid any risk of

accident.

Do not exceed 5 km/h (3,10 mph) .