Checking and setting the tension of the drive belt

Check the tension of the drive belt after the first 5 hours of operation. Retension

the belt if necessary.

Check the drive belt after every 50 hours of operation.

i

You need a Phillips screwdriver to remove and assemble the cover.

i

You need a size A/F 17 wrench to set the tension of the drive belt.

Disconnect the power supply

Switch off the main switch.

Remove the protective cover

Unscrew the bolts and set the protective cover down on the motor.

Check the tension of the drive belt

Take hold of a drive belt with one hand and turn it through 90 degrees.

i

To turn the drive belt through more than 90 degrees, you must retension the belt.

Retension the drive belt

Unscrew the locking nuts.

Turn the adjusting bolt to set the tension of the drive belt.

Then screw the locking nuts tight again.

Assemble the protective cover

Lift up the protective cover and line it up with the protective motor housing.

Screw the protective cover back onto the protective motor housing.

22

Maintenance

Summary of Contents for HM 70

Page 1: ...Operating instructions HM 70 Grain mill Translation of the original operating instructions...

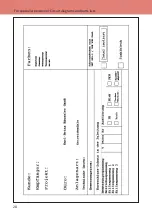

Page 28: ...28 For specialist personnel Circuit diagrams and parts lists...

Page 29: ...29 For specialist personnel Circuit diagrams and parts lists...

Page 30: ...30 For specialist personnel Circuit diagrams and parts lists...

Page 31: ...31 For specialist personnel Circuit diagrams and parts lists...

Page 32: ...32 For specialist personnel Circuit diagrams and parts lists...

Page 33: ...33 For specialist personnel Circuit diagrams and parts lists...

Page 34: ...34 For specialist personnel Circuit diagrams and parts lists...

Page 35: ...35 For specialist personnel Circuit diagrams and parts lists...

Page 55: ...19 Accessories Sifting elements Sifting elements with mesh of varying lengths 55 Accessories...

Page 56: ...20 EC Declaration of Conformity 56 EC Declaration of Conformity...